ALPHA 2.0

The CMM offers easy access to the measurement volume and easy loading and integration with part transportation systems.

Flexible gantry coordinate measuring machine for large workpieces

ALPHA 2.0 Classic is a multi-purpose flexible CMM for the dimensional inspection of large castings and machined parts. When equipped with optical scanning sensors, the system can rapidly digitize millions of data points on freeform components. This makes it an ideal reverse engineering and inspection system for the die and mold manufacturing process.

ALPHA 2.0 Performance is a high-performance gantry CMM that, thanks to its high-rigidity silicon carbide ram and sophisticated multisensor temperature compensation, guarantees high accuracy and ease of use under all operating conditions.

ALPHA 2.0 Specifications

Available Size (X, Y, Z)

20.33.10 / 20.33.15 / 20.50.15 / 25.33.15 /

25.50.15 / 25.33.18 / 25.50.18

Accuracy₂

From 3.5μm + 3.5 L/1000, MPE(E0/E150)₁) [18-22 °C]

From 3.5μm + 6.5 L/1000, MPE(E0/E150)₁) [16-26 °C]

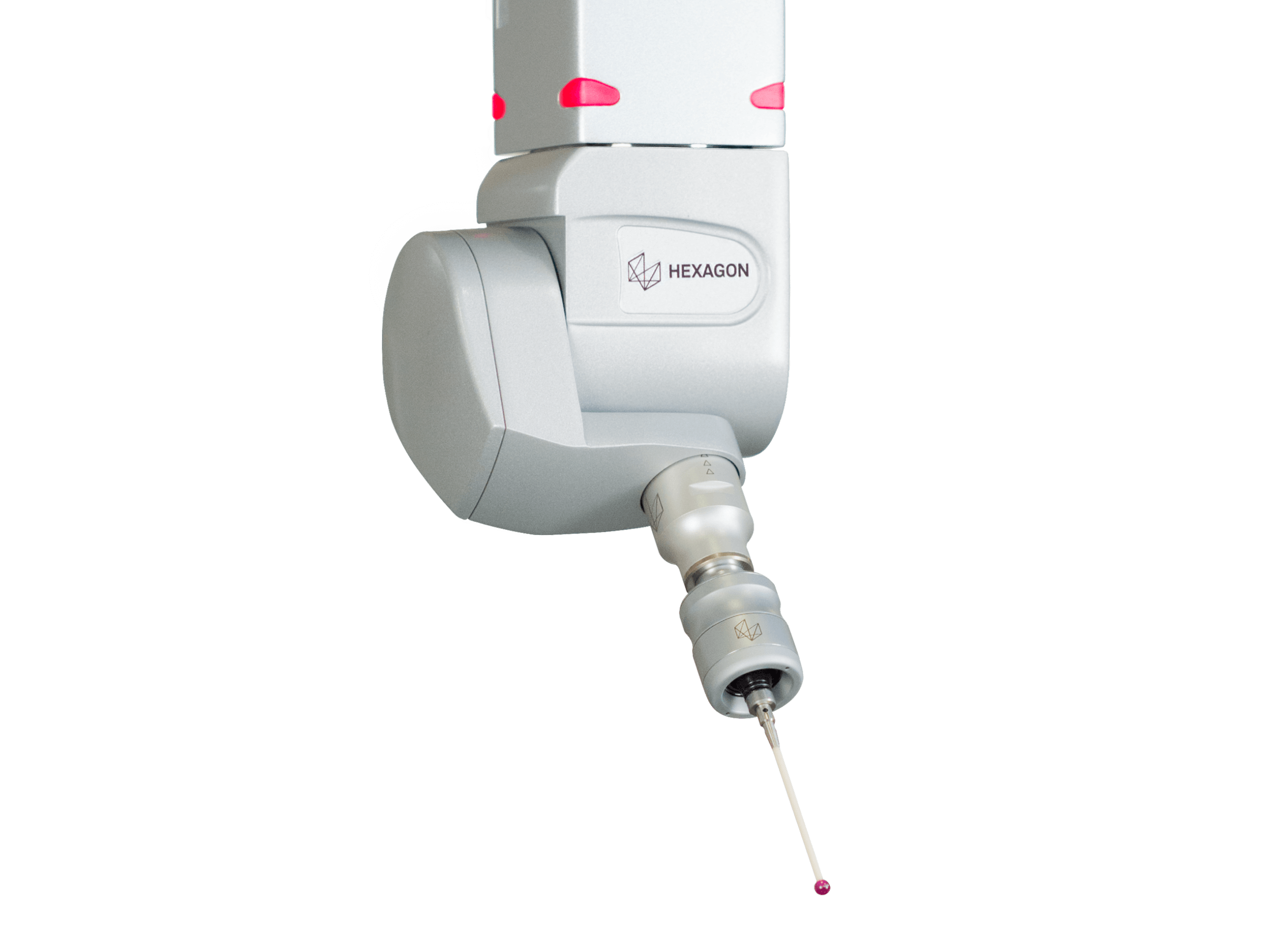

Probe type compatibility

Touch trigger probe

Scanning probe

Laser scanner probe

Automation ready

YES

Temperature specification

18 - 22 °C

16 - 26 °C

Overall Dimensions (mm) | |||

|---|---|---|---|

Model | LX | LY | LZ |

20.33.10 | 3460 | 4280 | 3560 |

20.33.15 | 3460 | 4280 | 4560 |

20.50.15 | 3460 | 5980 | 4560 |

25.33.15 | 3960 | 4280 | 4560 |

25.50.15 | 3960 | 5980 | 4560 |

25.33.18 | 3960 | 4280 | 4860 |

25.50.18 | 3960 | 5980 | 4860 |

₁ E0, MPE/E150, MPE specifications are to be formally understood as E0,MPE* /E150, MPE* for the case where non-normal CTE material calibrated test lengths are used.

₂ According to ISO 10360-2 (2009)

You may be interested in...

© 2024 Hexagon AB and/or its subsidiaries