© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

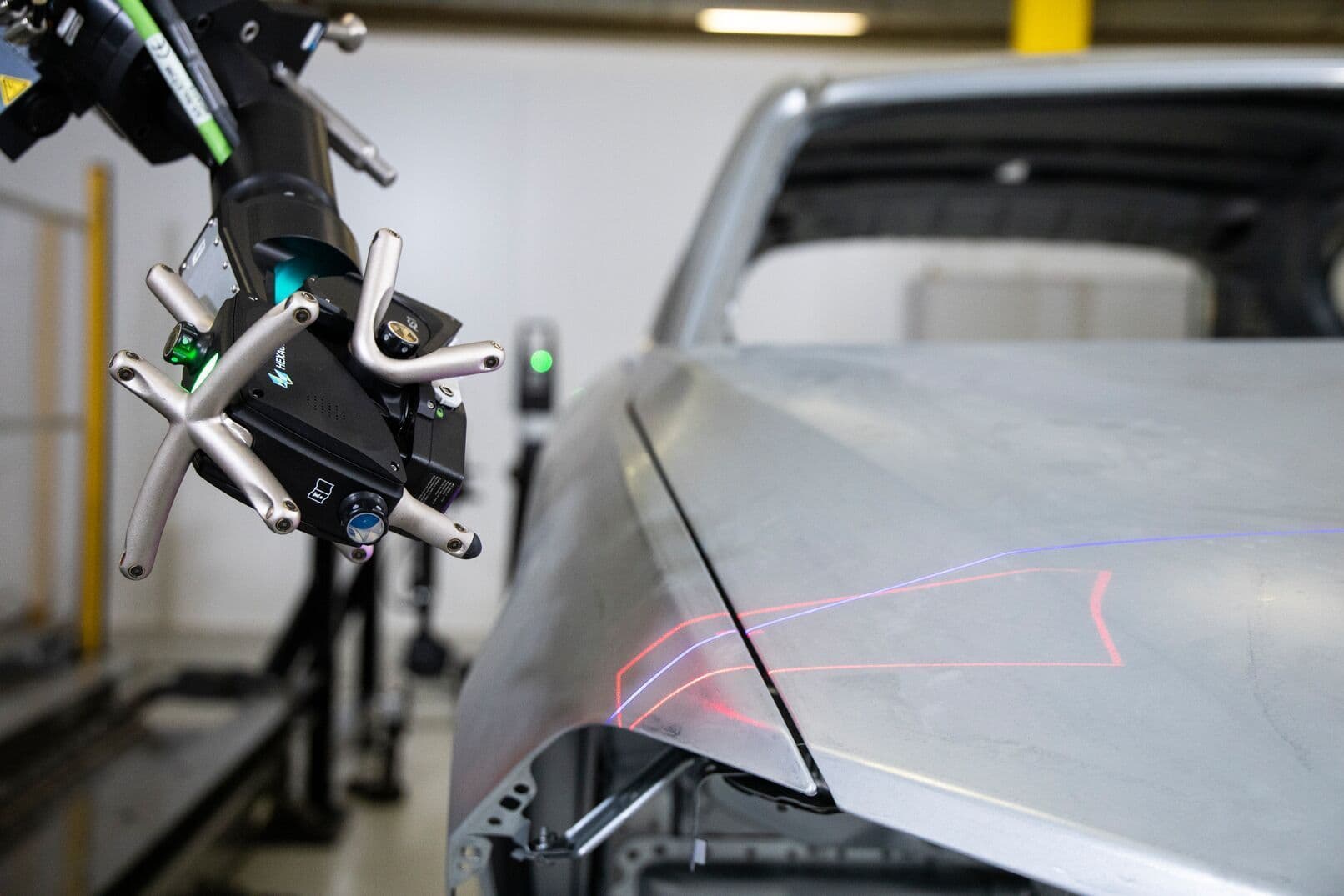

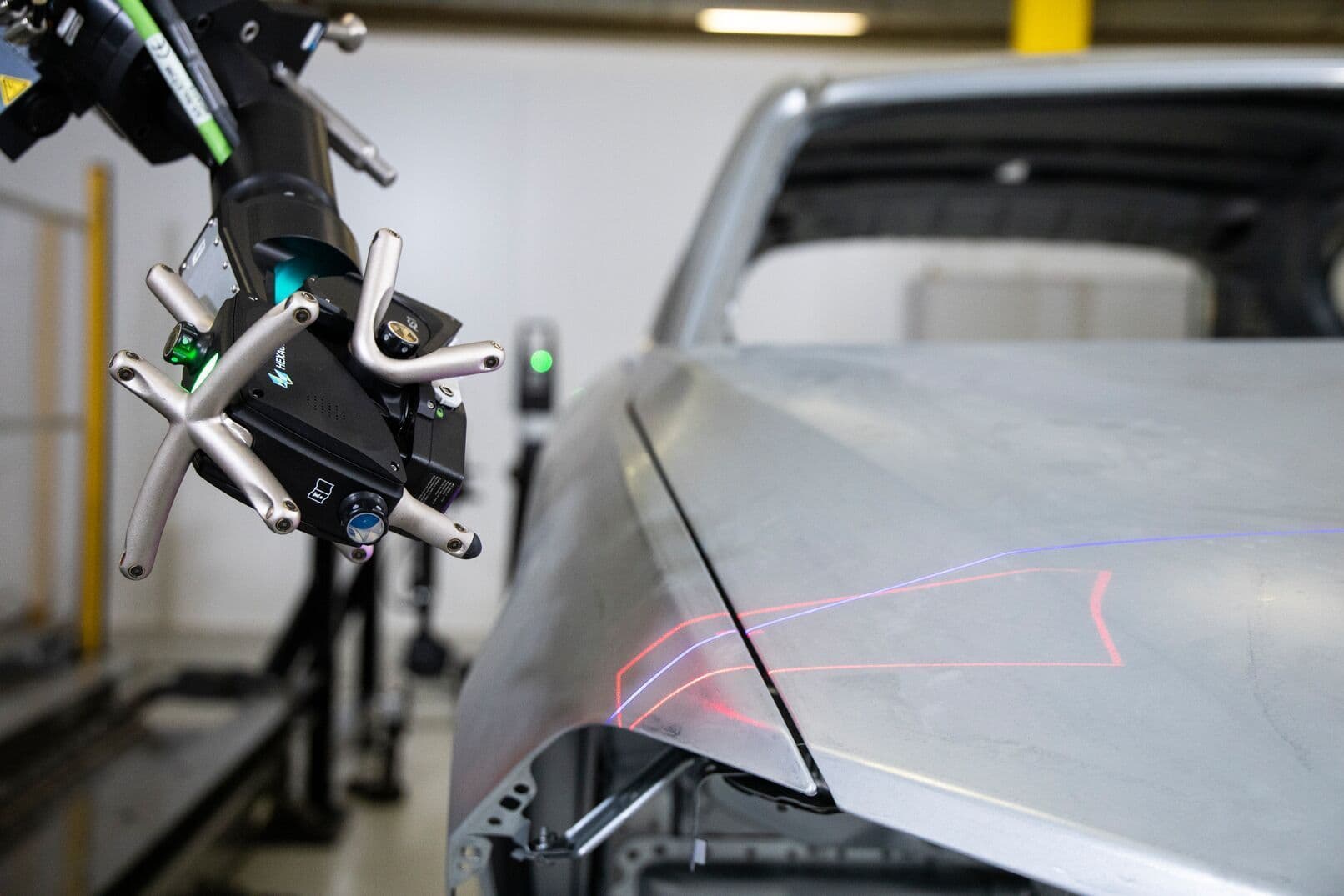

Laser Tracker Automated Inspection

Our laser tracker automated inspection solutions are inherently customized, built out according to very specific user requirements that define everything from size and components to initial and future functionalities. This bespoke approach is why our solutions are driving better quality and higher productivity in manufacturing instances all over the world.

The Leica Absolute Tracker AT960 is capable of six degrees of freedom (6DoF) measurement as standard, allowing the use of a scanner, camera or probe from up to 30 metres away. With the Absolute Scanner AS1, Leica T-Scan 5 and Leica T-MAC sensors, this process can be automated, with each easily mountable on any standard industrial robot arm. Then a fully automated inspection setup is just a matter of programming and accessories, from turntables, sliders and robots to isolation walls, built-in control stations and tool changers for automatic sensor switching.

With the unique direct scanning functionality of the Leica Absolute Tracker ATS600, automated inspection is simpler than ever before. There’s no need for a sensor or an operator at the point of measurement, so components can just be brought into the tracker’s field of view and automatically inspected with just a few software clicks. No need to move the tracker, no need to manually scan. With its unique selective scanning functionality, you just tell the ATS600 the area it should measure and how much detail you need, and press start.

Training and Resources

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Laser Tracker Automated Inspection

Our laser tracker automated inspection solutions are inherently customized, built out according to very specific user requirements that define everything from size and components to initial and future functionalities. This bespoke approach is why our solutions are driving better quality and higher productivity in manufacturing instances all over the world.

The Leica Absolute Tracker AT960 is capable of six degrees of freedom (6DoF) measurement as standard, allowing the use of a scanner, camera or probe from up to 30 metres away. With the Absolute Scanner AS1, Leica T-Scan 5 and Leica T-MAC sensors, this process can be automated, with each easily mountable on any standard industrial robot arm. Then a fully automated inspection setup is just a matter of programming and accessories, from turntables, sliders and robots to isolation walls, built-in control stations and tool changers for automatic sensor switching.

With the unique direct scanning functionality of the Leica Absolute Tracker ATS600, automated inspection is simpler than ever before. There’s no need for a sensor or an operator at the point of measurement, so components can just be brought into the tracker’s field of view and automatically inspected with just a few software clicks. No need to move the tracker, no need to manually scan. With its unique selective scanning functionality, you just tell the ATS600 the area it should measure and how much detail you need, and press start.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

This product does not offer any software downloads.