© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

First-class solution for metal forming manufacturing processes

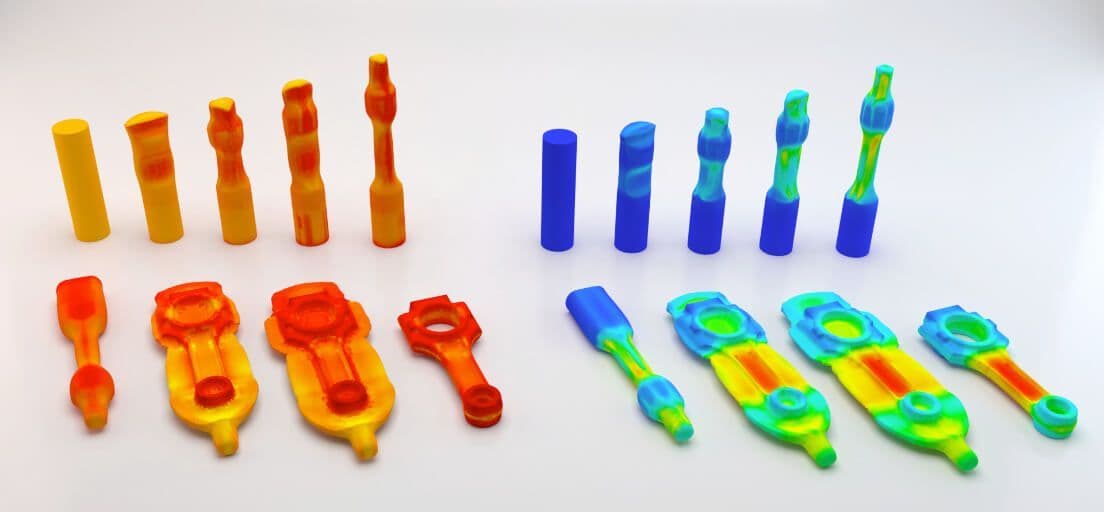

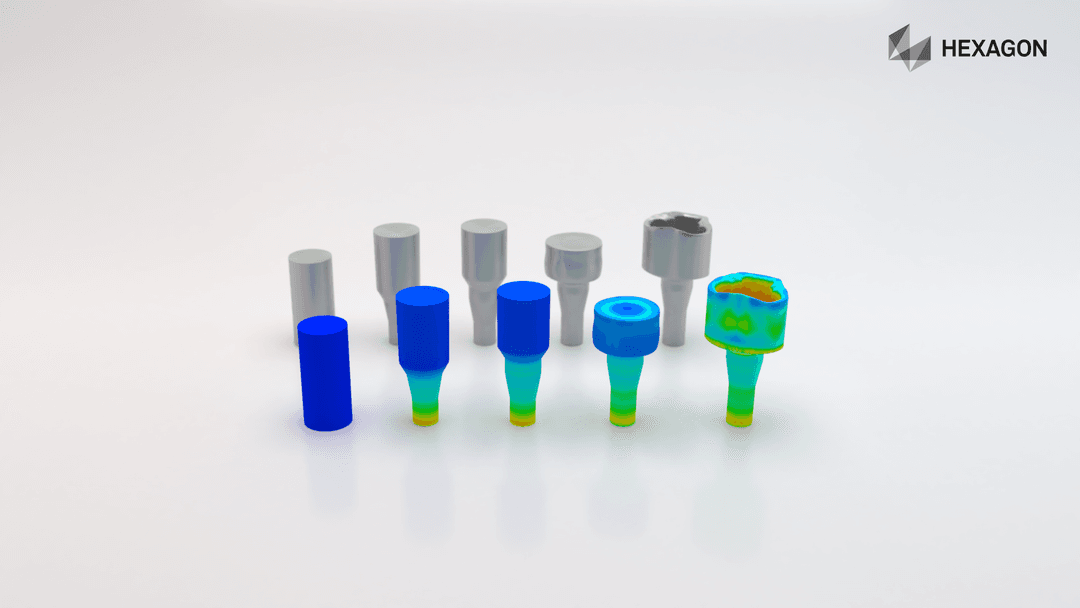

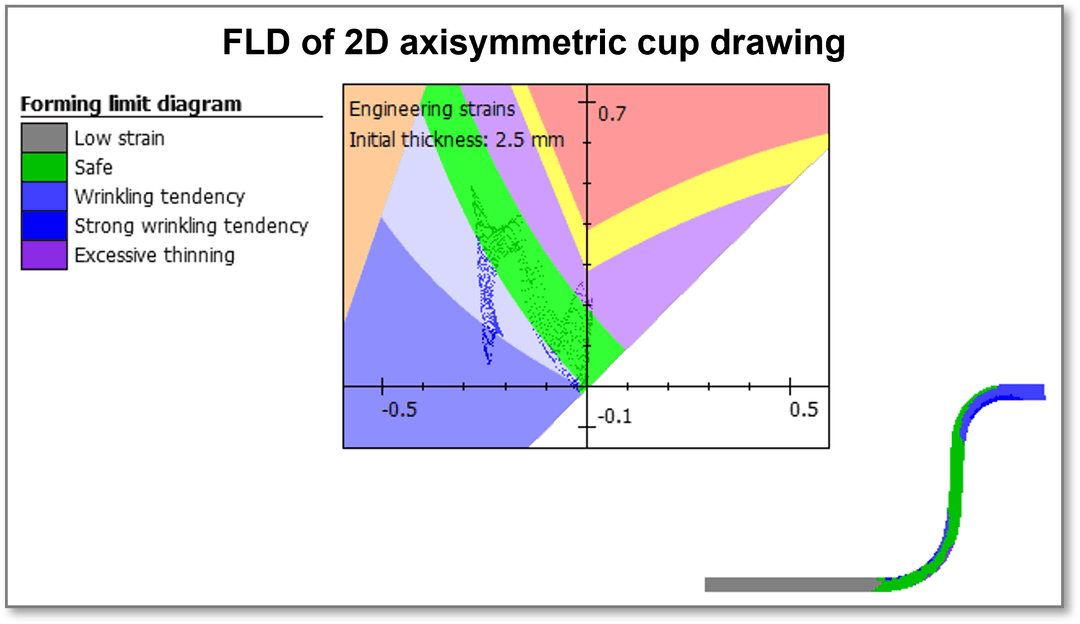

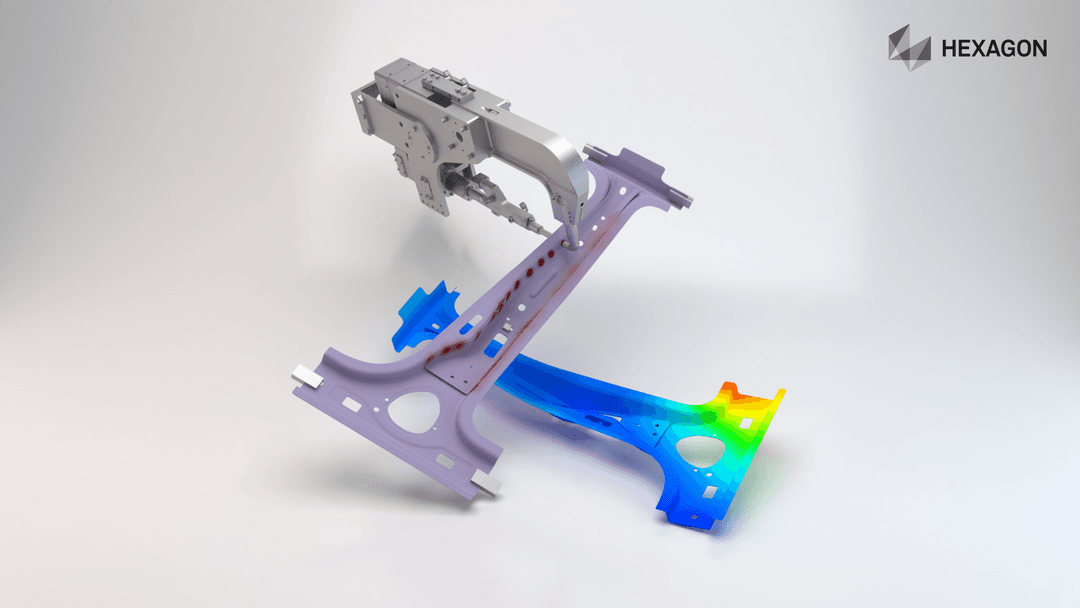

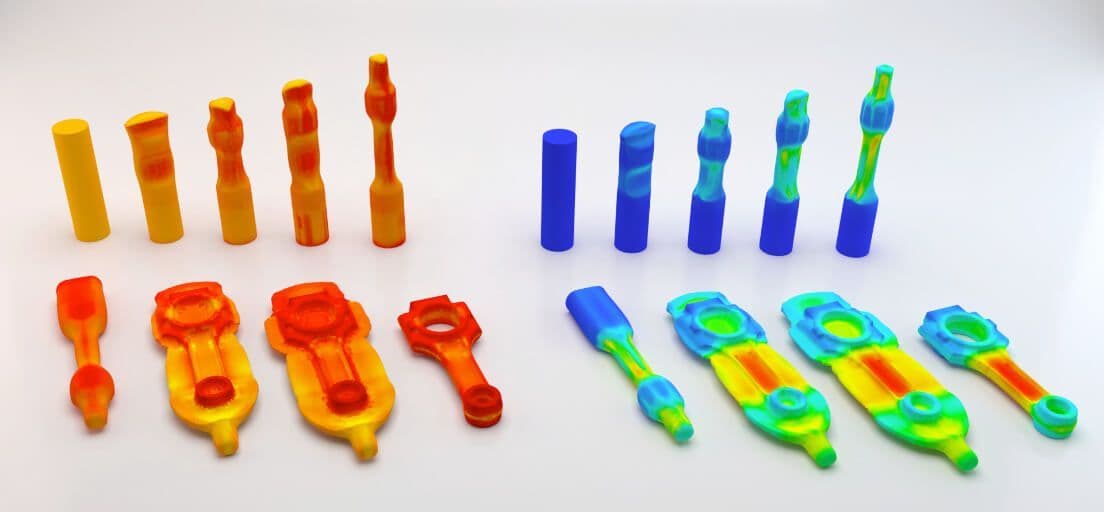

Simufact Forming is an established software solution for the simulation of metal forming manufacturing processes. The software covers all essential areas of forming technology: forging, cold forming, sheet metal forming, all major incremental processes and mechanical joining.

Simufact Forming provides support in microstructure simulation, calculation of die load, material flow and prediction of material properties in the course of conventional and inductive heat treatment. Furthermore, thermo-mechanical joining methods of pressure welding are also supported.

Benefits And Features

Unlock Precision and Efficiency in Metal Forming with Simufact Forming

Advanced Process Simulation

Simufact Forming stands out as a versatile tool, simulating a wide range of metal forming processes such as incremental processes, mechanical joining, and pressure welding. With its ability to accurately predict component properties during and after manufacturing, it ensures that your products meet the highest standards of quality and performance.

Precision and Predictability

Harness the power of highly accurate material descriptions to predict component properties with precision. Simufact Forming allows manufacturers to foresee the outcomes of each manufacturing stage, ensuring that the final product aligns with design specifications and quality requirements.

Seamless Integration and Usability

Simufact Forming's open architecture facilitates easy and seamless import and export of results through the UNV data format, integrating smoothly with other Hexagon software solutions. Its user-friendly and intuitive design means that even users without expert knowledge can quickly adopt the software, streamlining the manufacturing process and minimizing learning curves.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

First-class solution for metal forming manufacturing processes

Simufact Forming is an established software solution for the simulation of metal forming manufacturing processes. The software covers all essential areas of forming technology: forging, cold forming, sheet metal forming, all major incremental processes and mechanical joining.

Simufact Forming provides support in microstructure simulation, calculation of die load, material flow and prediction of material properties in the course of conventional and inductive heat treatment. Furthermore, thermo-mechanical joining methods of pressure welding are also supported.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today