© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

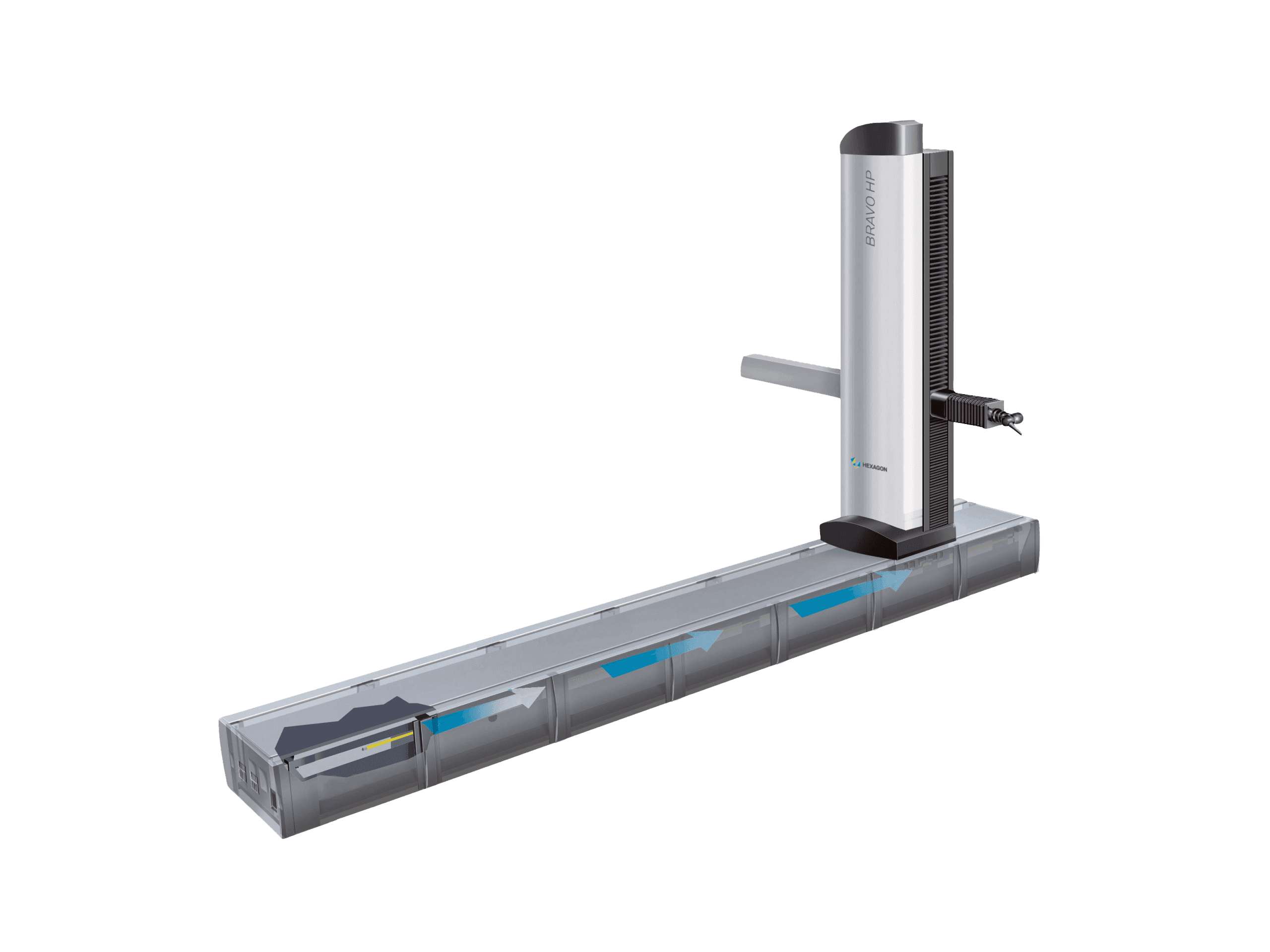

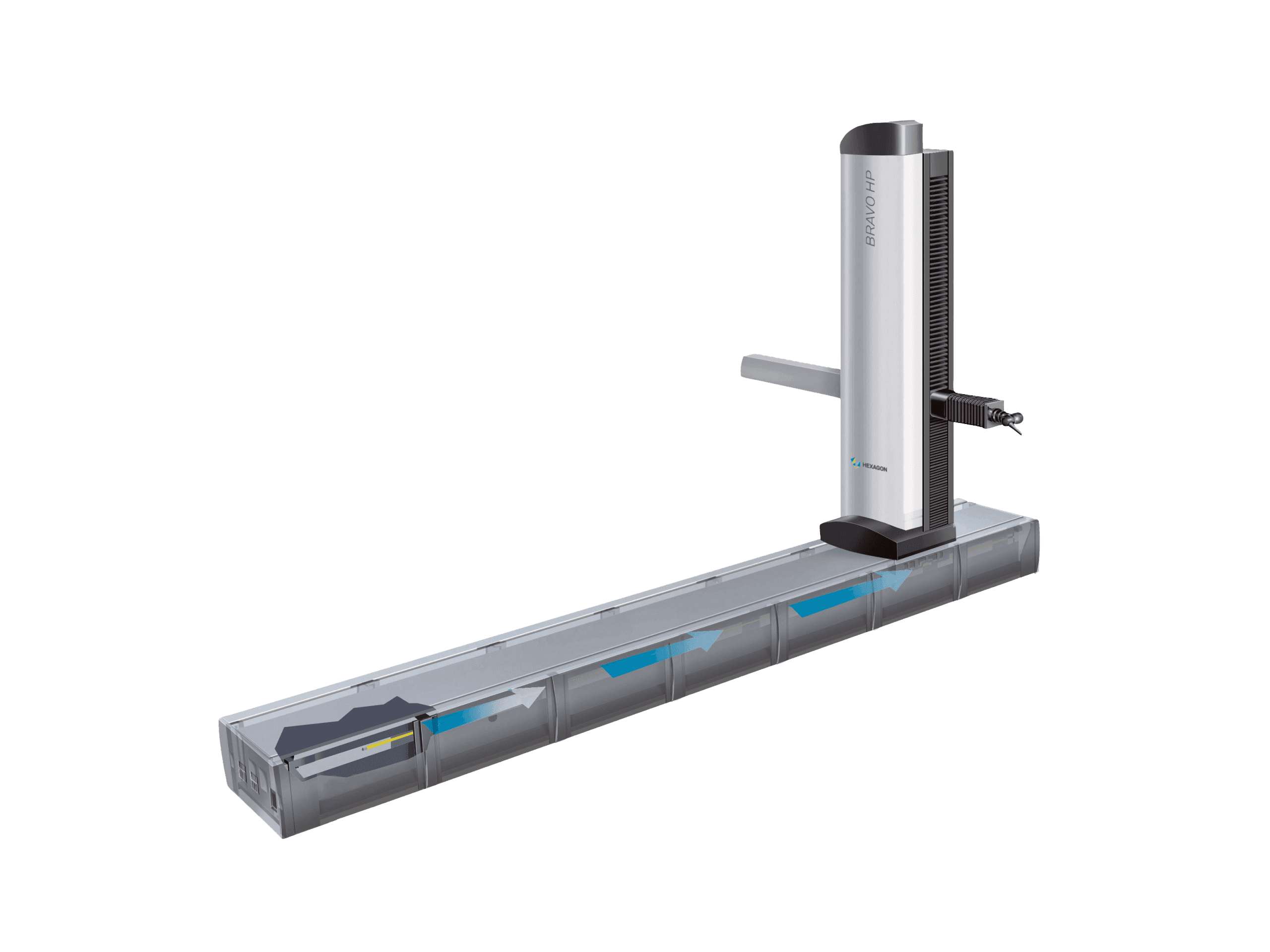

Sheet metal inspection at its best

The BRAVO HP has been designed to meet in an optimum way the requirements of dimensional inspection and analysis of bodyshells, chassis and subassemblies on the shop floor. It is characterized by high dynamics and accuracy. BRAVO HP belongs to the BRAVO line which also includes BRAVO HD and BRAVO HA. The stable, precise mechanical structure, the integrated temperature compensation system, a wide range of probes, probe heads, wrists and accessories as well as a state-of-the-art software package make it an effective CMM that is particularly well suited for operation in shop-floor environments, metrology labs and QC rooms.

Training and Resources

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Sheet metal inspection at its best

The BRAVO HP has been designed to meet in an optimum way the requirements of dimensional inspection and analysis of bodyshells, chassis and subassemblies on the shop floor. It is characterized by high dynamics and accuracy. BRAVO HP belongs to the BRAVO line which also includes BRAVO HD and BRAVO HA. The stable, precise mechanical structure, the integrated temperature compensation system, a wide range of probes, probe heads, wrists and accessories as well as a state-of-the-art software package make it an effective CMM that is particularly well suited for operation in shop-floor environments, metrology labs and QC rooms.

Evaluate your device's health with Eclipse Compass.

This tool reviews your hardware's status and usage, providing a clear score and actionable insights. Instantly find out if your device is ready, needs service, or requires an upgrade, enabling informed decisions and minimizing downtime.

BRAVO HP Specifications

| Available Size (X, Y, Z)₁ | |

|---|---|

XX.16.XX Available X strokes: 4000, 6000, 7000, 9000 mm Available Z strokes: 2100, 2500, 3000 | |

| Accuracy₂ | |

From 15 + 10 L/1000, < 40 μm (Single Arm), 18 - 22 °C From 30 + 10 L/1000, < 50 μm (Double Arm), 18 - 22 °C | |

| Probe type compatibility | |

Touch trigger probe Laser scanner probe | |

| Automation ready | |

YES | |

| Temperature specification | |

18 - 22 °C 16 - 26 °C 16 - 32 °C |

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

This product does not offer any software downloads.