© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

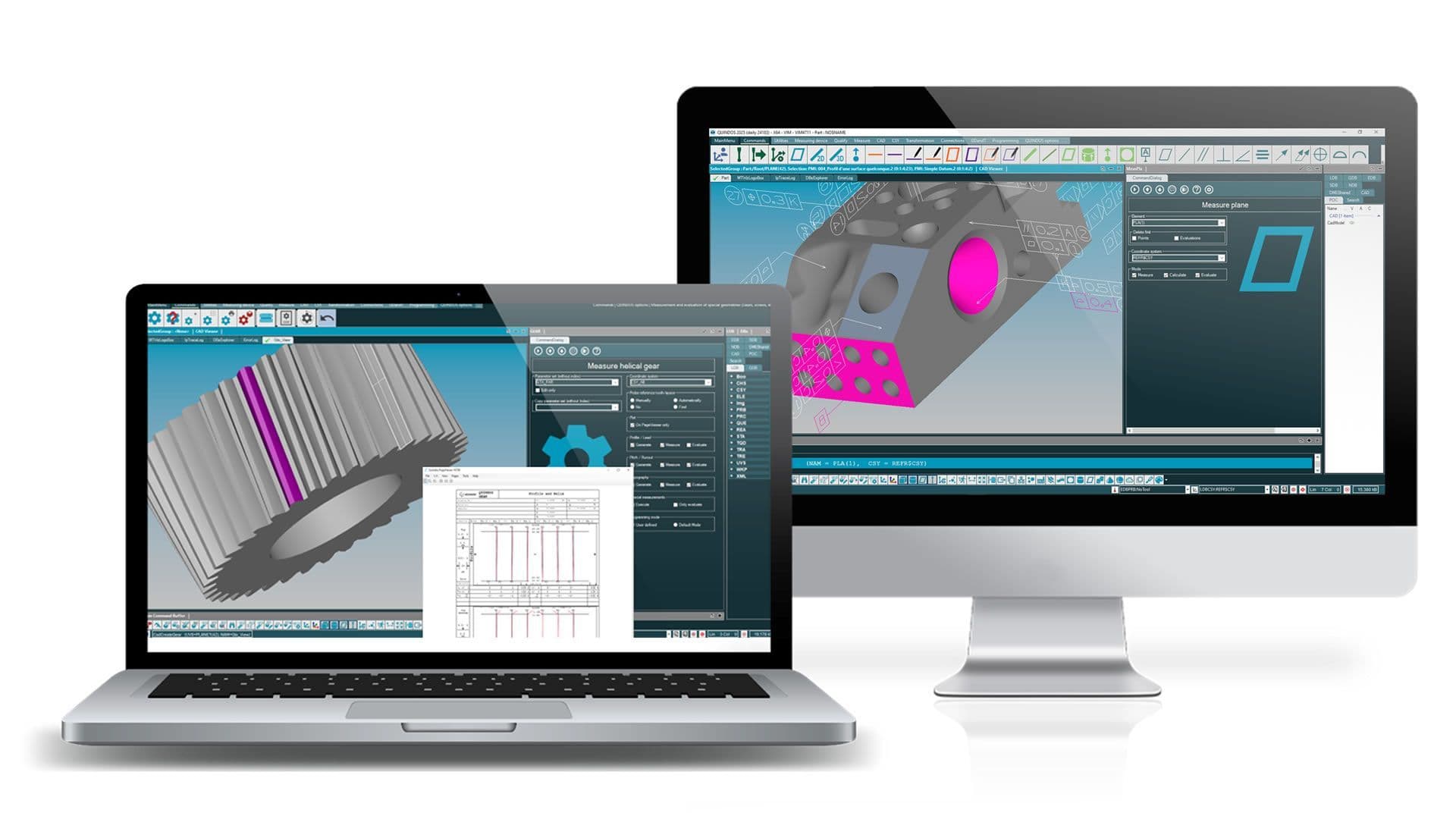

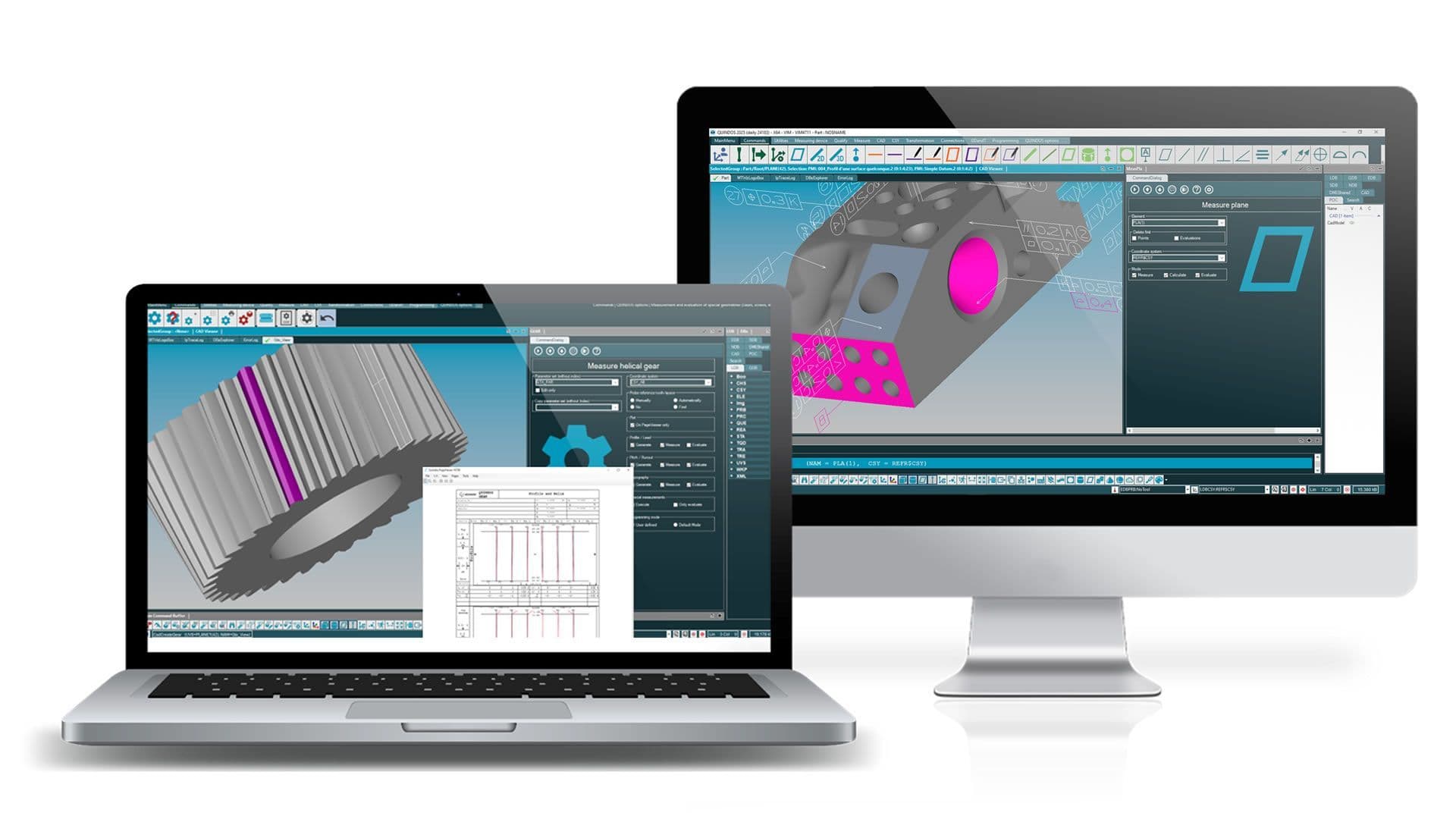

Powerful and easy-to-use optional programs with unlimited flexibility

QUINDOS manages highly demanding metrology projects, using special selection dialogues to create measurement programs. An icon-based UI makes QUINDOS easy to use for both new and experienced users. QUINDOS is compatible with every CMM that uses the I++DME interface, providing a common solution across multiple manufacturing processes.

Benefits And Features

The leading modular metrology software for special geometries used in aerospace, energy, automotive, and engineering

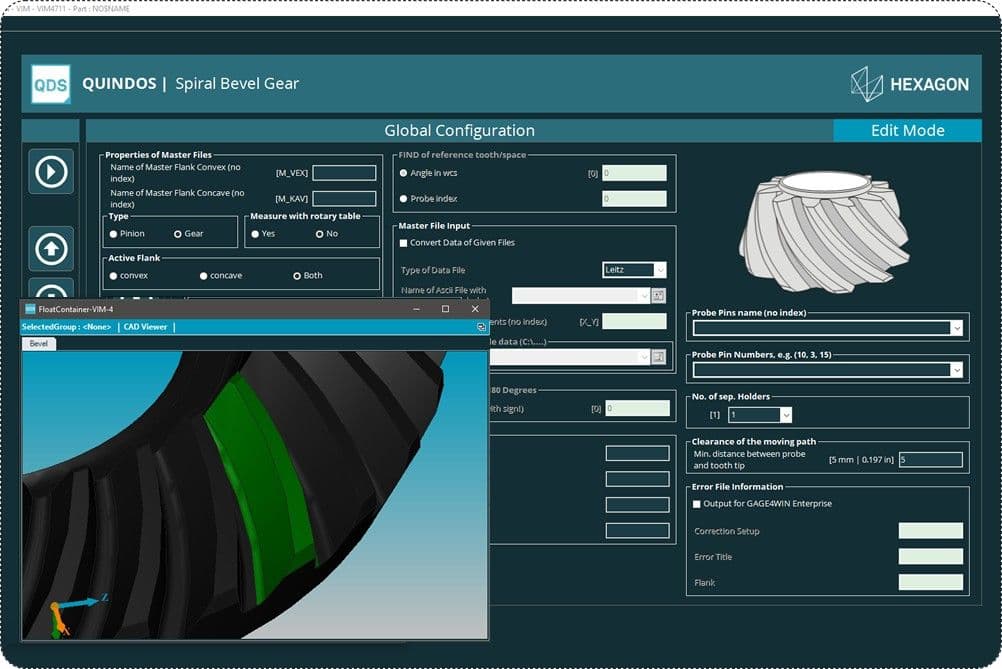

Modular Flexibility

Choose from a wide range of modules to build precise measurement applications. Add Special Geometry modules to the core QUINDOS application to measure demanding gear components with unique evaluation standards

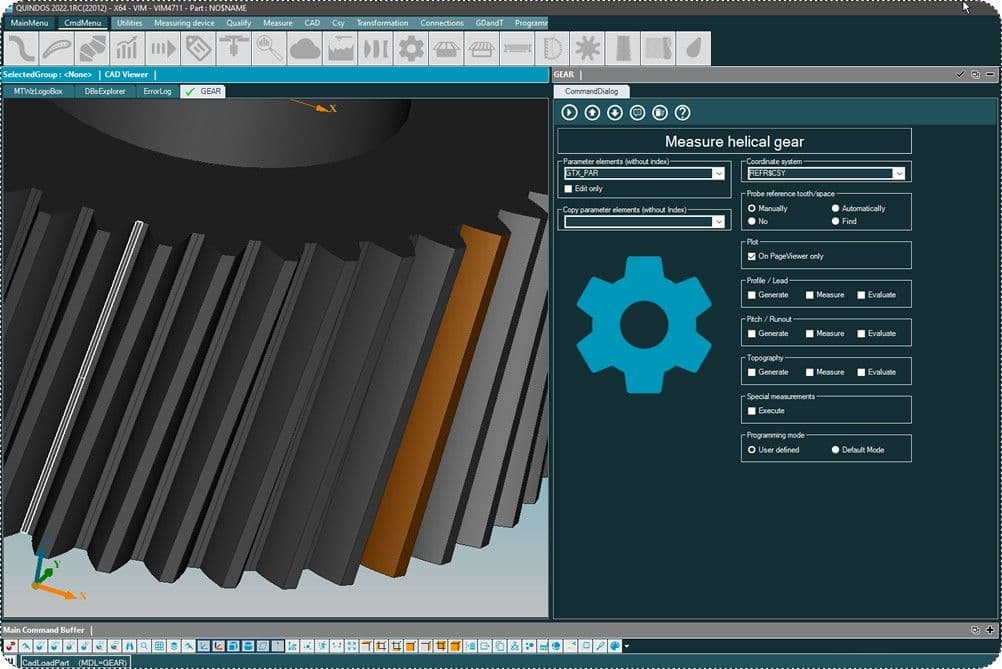

Programming Power

Highly programmable for the most complex geometries, QUINDOS offers structured programming and the option to build a custom command library with UI support.

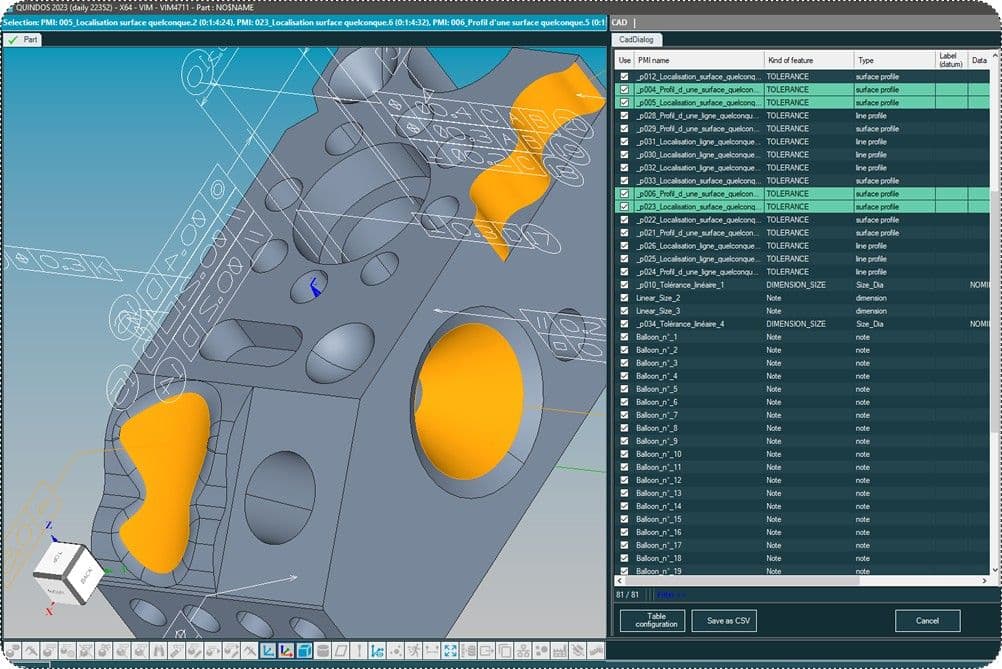

PMI ready

Automate programme creation by utilising PMI data embedded within native 3D models. Create measurement routines using PMI data with just a few clicks within a highly visual CAD enabled environment.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Powerful and easy-to-use optional programs with unlimited flexibility

QUINDOS manages highly demanding metrology projects, using special selection dialogues to create measurement programs. An icon-based UI makes QUINDOS easy to use for both new and experienced users. QUINDOS is compatible with every CMM that uses the I++DME interface, providing a common solution across multiple manufacturing processes.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

Register today for full access to out download area and more.

| Version | Name | Date Released | File Size | |

|---|---|---|---|---|

| 2025.2.3 | QUINDOS | 2026-01-16 | -- | |

| 2025.1.7 | QUINDOS | 2024-06-30 | -- |

Frequently Asked Questions

These are listed in the release notes of the respective version (s. chapter 1, Release Notes QUINDOS Version 2022.2)

Also listed in our quick guide.

Please follow the instructions of the QUINDOS Basic installation manual here. It contains additional FAQs.

QUINDOS checks your SMA contract before installation. If you want to check whether you can install a newer version of QUINDOS before you download the version, you can find the required SMA date for a main release version in the release notes in the chapter 'Prerequisites - before installing QUINDOS'.

Furthermore, the SMA date is displayed on our download server for the respective version. This date should cover your current QUINDOS SMA contract. To check your SMA contract period, open the current QUINDOS license file. Open the folder C:\ProgramData\Hexagon\Quindos7\Licenses(for versions < QUINDOS 2021.2 C:\Program Files (x86)\Quindos7\Licenses) in your QUINDOS installation and open the license with an editor. In the header, you will find your contract number as well as the start and end date.

QUINDOS Basis supports the import of the standardized formats IGES and STEP (STEP AP 203, AP 214). For the use of native 3D CAD formats, you need an additional converter license. The native formats supported by the respective main release version are listed in the release notes.

Please select the chapter 'DATAKIT converter licenses'. QUINDOS converters are available for the formats CATIA, Pro Engineer/Creo, Siemens NX/UG, STEP 242, Parasolid, SolidWorks, SolidEdge, JT B-Rep.

Due to a computer change the hardware ID of the computer has changed. The license must be renewed for this computer. With a valid SMA contract, the license transfer is free of charge. Hints for backup and transfer of the existing working environment are given in the QUINDOS Quick Tip

QUINDOS supports automated inspection planning with PMIs. The special module was released for Siemens NX 10 and CATIA V5. It enables you to carry out your inspection planning based on standardized measurement and evaluation strategies quickly and efficiently. Furthermore, PMIs can be integrated into models supplemented from digital drawings using OCR technology or based on statistics files (Q-DAS format DFD).