PC-DMIS

Smart measurement data you can trust

As well as meeting the latest ISO and ASME standards, PC-DMIS advances your coordinate measuring machines (CMMs) and metrology systems to support your organization’s productivity and cost-saving objectives.

Benefits And Features

Industry-leading, cross-platform metrology software for any inspection challenge.

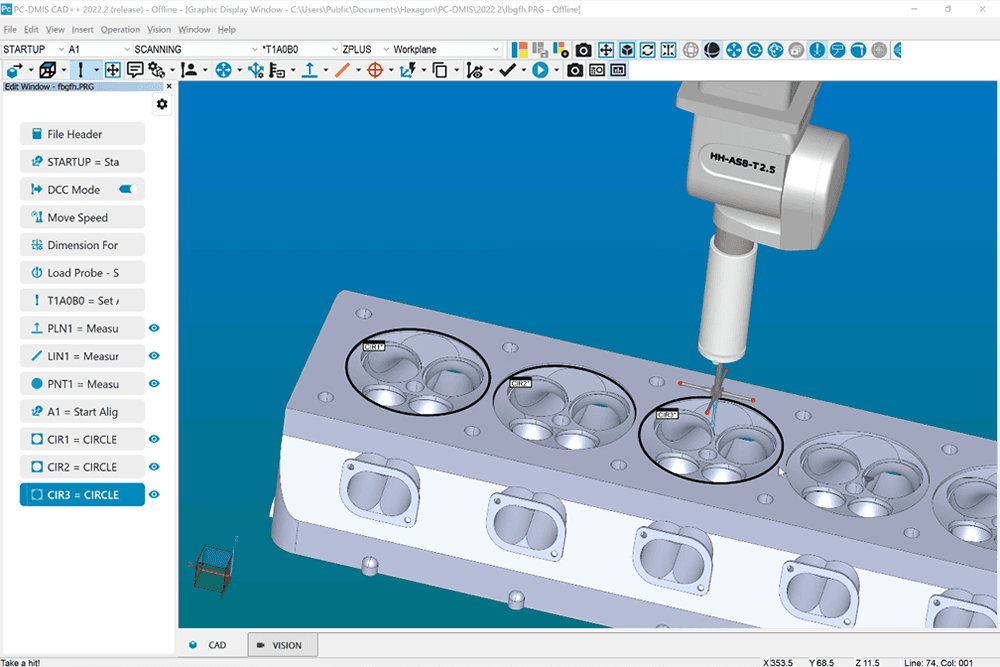

One universal metrology software for any device

Whether it's used with stationary CMMs, portable arms, vision systems or trackers, programmers and operators experience the same great looking user interface across all device types. With only one software to learn there’s no need to invest in a new application for each device.

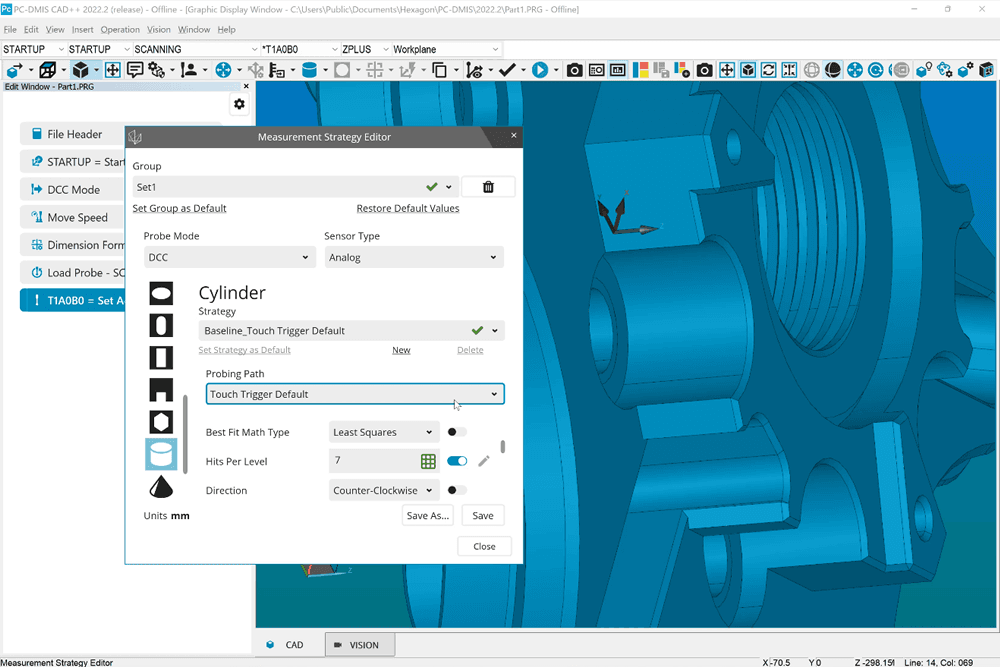

Time-saving features and automation

PC-DMIS offers a wide variety of smart features designed to streamline measurement processes, enhance productivity, and improve efficiency. They reduce the time required for setup, execution, and analysis, allowing users to focus more on quality control and decision-making.

PC-DMIS Powered by Nexus

Connect PC-DMIS with a growing number of Nexus applications which extend and enhance its core capabilities. Nexus applications such as Metrology Mentor and Metrology Reporting reduce CMM programming time and help inspection data to flow more freely across your organisation.

Training and Resources

Support

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2025 Hexagon AB and/or its subsidiaries