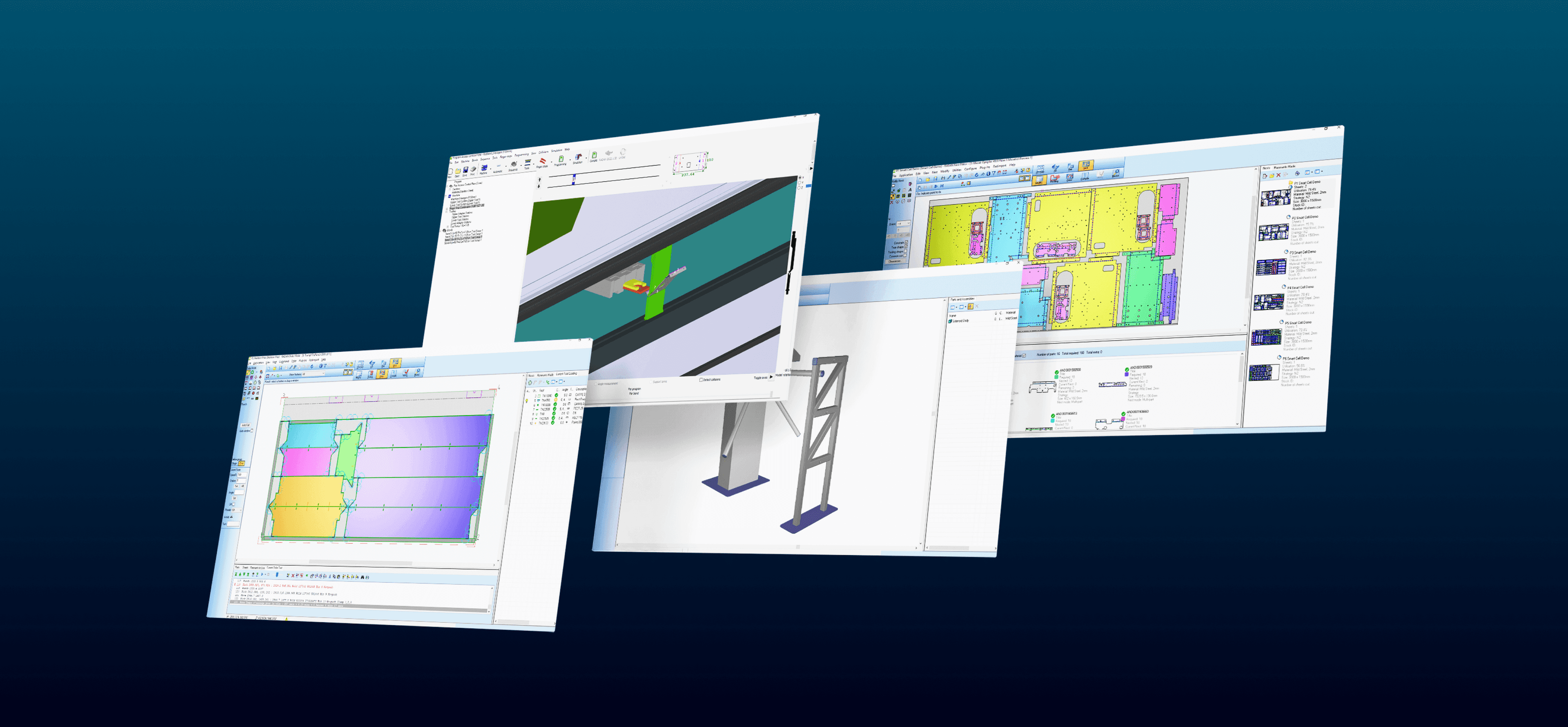

RADAN

Increased utilization of materials for the sheet metal industry

RADAN is a leading and machine-independent CAD/CAM/MES system designed for the sheet metal industry. The RADAN product family is a completely integrated solution for the design, handling and production of sheet metal parts.

Benefits And Features

An innovative CAM solution for sheet metal fabrication.

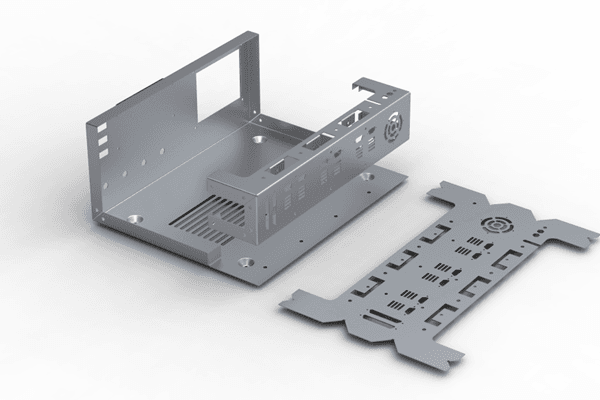

Sheet Metal Nesting

RADAN’s advanced true-shape nesting ensures maximum material utilization by intelligently arranging parts within a sheet. This minimizes waste, reduces material costs, and increases profitability while maintaining precision, making production more sustainable and cost-effective for sheet metal fabricators.

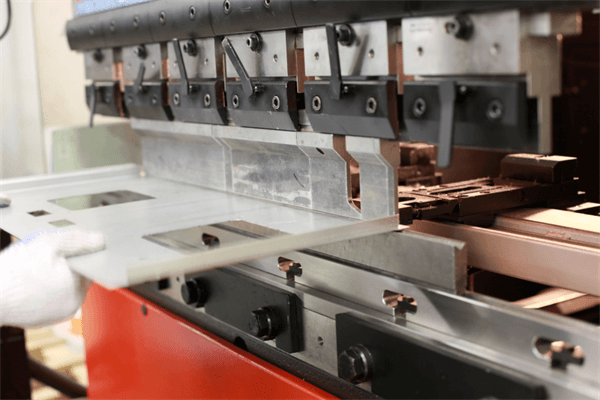

CNC Programming

RADAN automates CNC programming for punching, profiling, and bending operations, creating optimized toolpaths for various machines. This reduces setup time, minimizes programming errors, and increases efficiency, allowing manufacturers to streamline production while improving accuracy and repeatability.

Fast & Accurate Quoting

RADAN’s intelligent quoting system generates fast, consistent, and accurate cost estimates using real manufacturing data. It considers material, machine time, and labor, enabling fabricators to create competitive quotes quickly while ensuring profitability and reducing the risk of underpricing.

What's New

Learn about RADAN 2025.1

The latest RADAN release introduces powerful enhancements that streamline operations, improve part traceability, and deliver measurable savings on time and cost. With improved automation, better feedback in error handling, and tighter integration across the suite, RADAN 2025.1 continues to drive productivity in sheet metal fabrication.

Training and Resources

Support

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2025 Hexagon AB and/or its subsidiaries