© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

A diverse yet easy-to-use feature set

With an unrivaled out-of-the-box experience, SURFCAM can help your business to become even more productive and profitable.

The benefits of using SURFCAM include:

Benefits And Features

An easy-to-use production machining CAM solution.

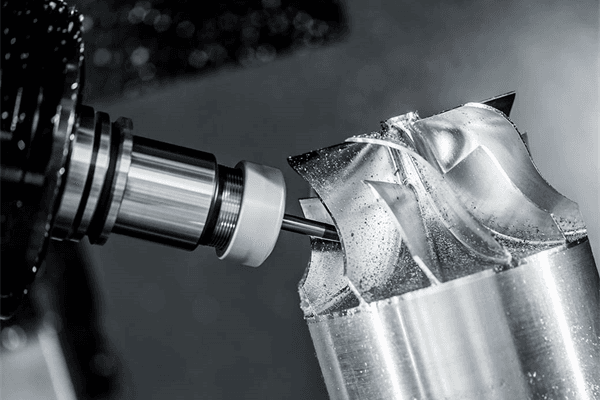

High-Performance 2 & 3 Axis Machining

SURFCAM offers a cost-effective CAM solution with a comprehensive toolpath library. The 2-axis system, enhanced with TRUEMill, boosts material removal rates while extending tool life. The 3-axis system ensures precision, high-speed machining, and superior surface finishes with optimized tool motion.

Advanced Multi-Axis Control for Complex Parts

The 4- & 5-axis machining system provides full tool motion visualization, collision checking, and precise control for challenging applications. With optimized toolpath containment and gouge avoidance, it ensures safe and efficient multi-axis machining for intricate components.

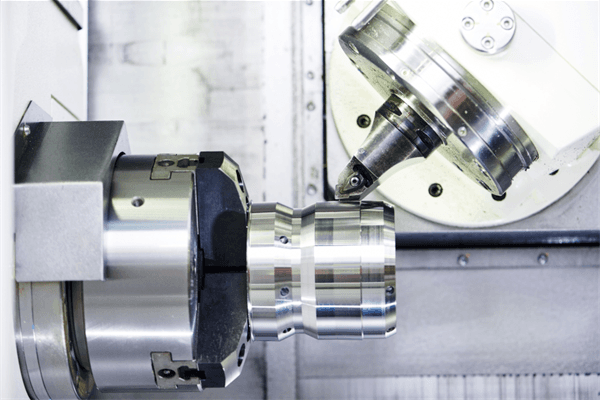

Versatile Lathe and Wire EDM Capabilities

SURFCAM Lathe supports turning, grooving, threading, and advanced canned cycles for efficient machining. The Wire EDM system offers three specialized strategies tailored to meet diverse cutting requirements, ensuring precision and reliability in wire-cut applications.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

A diverse yet easy-to-use feature set

With an unrivaled out-of-the-box experience, SURFCAM can help your business to become even more productive and profitable.

The benefits of using SURFCAM include:

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today