© 2025 Hexagon AB and/or its subsidiaries

© 2025 Hexagon AB and/or its subsidiaries

CAM for CNC Machine Tool Programming

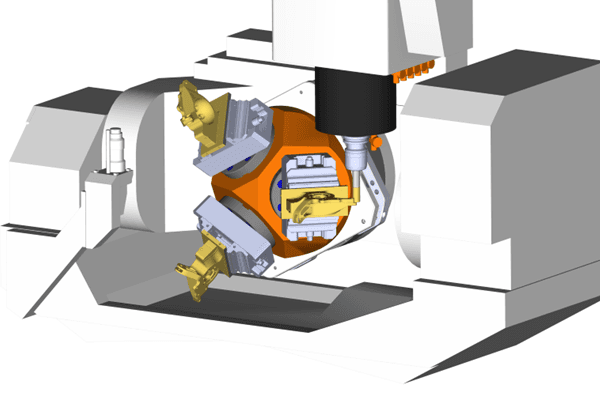

Powered by Artificial Intelligence and driven with Digital Twin technology. Revolutionize your manufacturing operations with true digital twin technology, artificial intelligence, next generation automation tools, and robust CAM programming to safely and efficiently drive all your CNC machinery.

Benefits And Features

Industry-leading CAM solution for production machining applications.

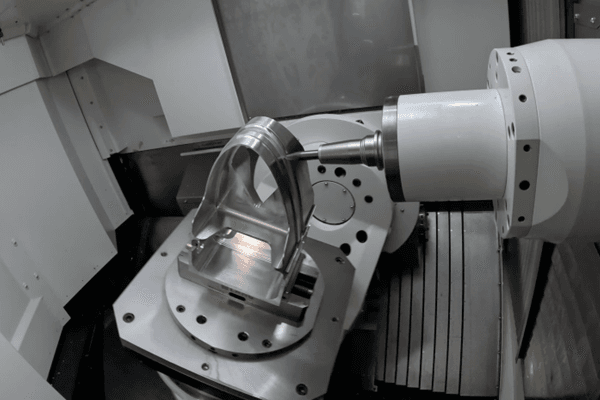

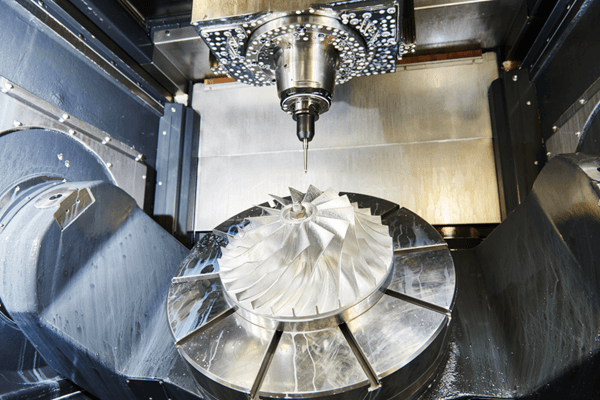

Milling 3- to 5-Axis

ESPRIT EDGE’s adaptive milling cycles support everything from 2.5-axis to continuous 5-axis machining, giving users precise control over toolpaths and strategies. This flexibility ensures high-quality surface finishes, reduced machining time, and the ability to handle complex geometries with confidence, making it ideal for any CNC machine.

Millturn and multi-tasking

Enables seamless synchronization of multi-spindle, multi-channel machines, optimizing tool engagement and cycle times. By automatically balancing operations, it reduces machine idle time, enhances productivity, and simplifies programming for complex parts, allowing manufacturers to fully leverage the capabilities of their multi-tasking machines..

Turn-key post processing

Factory-developed post processors that produce edit-free G-code are available for your machine tools. Users benefit from faster setup, fewer errors, and a highly automated workflow that maximizes efficiency while minimizing manual intervention on the shop floor.

You might be interested in...

Related products

Training and Resources

Support

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

CAM for CNC Machine Tool Programming

Powered by Artificial Intelligence and driven with Digital Twin technology. Revolutionize your manufacturing operations with true digital twin technology, artificial intelligence, next generation automation tools, and robust CAM programming to safely and efficiently drive all your CNC machinery.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today