Simulating porosity effects on NVH performance

Using porosity data from a set of physical prototypes, detailed NVH simulations can be conducted to specify meaningful porosity tolerances for regular inspections during production.

In early project phases, new part designs are tested virtually. Virtual testing is mostly performed on CAD models, perfect in geometry and material. Safety factors are applied to the results to make sure parts will last in real use cases, even if they may have minor geometry deviations and material imperfections such as porosity. Those safety factors often lead to overspecified designs, resulting in unnecessarily high procurement and manufacturing cost.

Using porosity data from a set of physical prototypes, detailed NVH simulations ensure desired performance criteria are met without unnecessarily increasing waste and cost of production.

Specify porosity tolerances in a physically meaningful way, to ensure desired NVH performance criteria are met without unnecessarily increasing waste and cost of production.

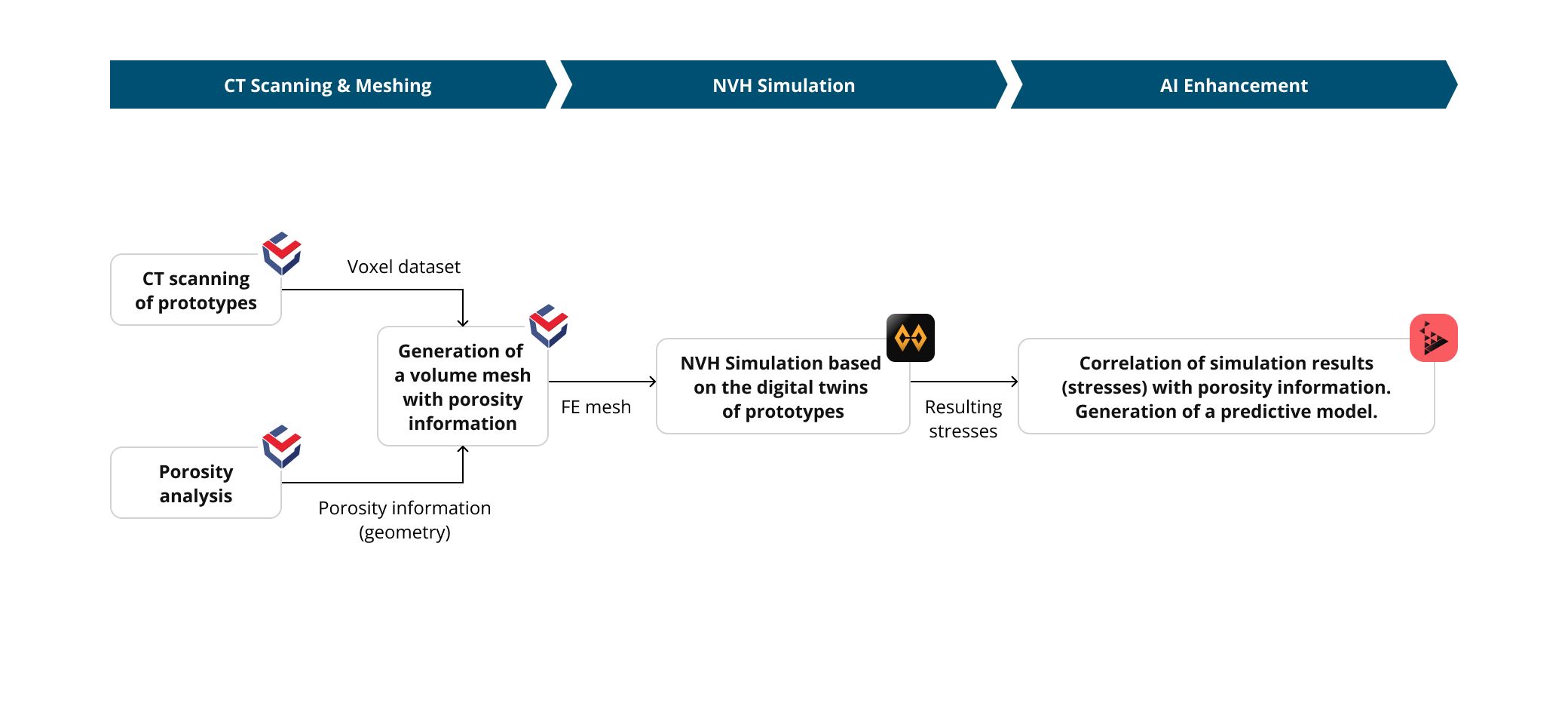

Our approach

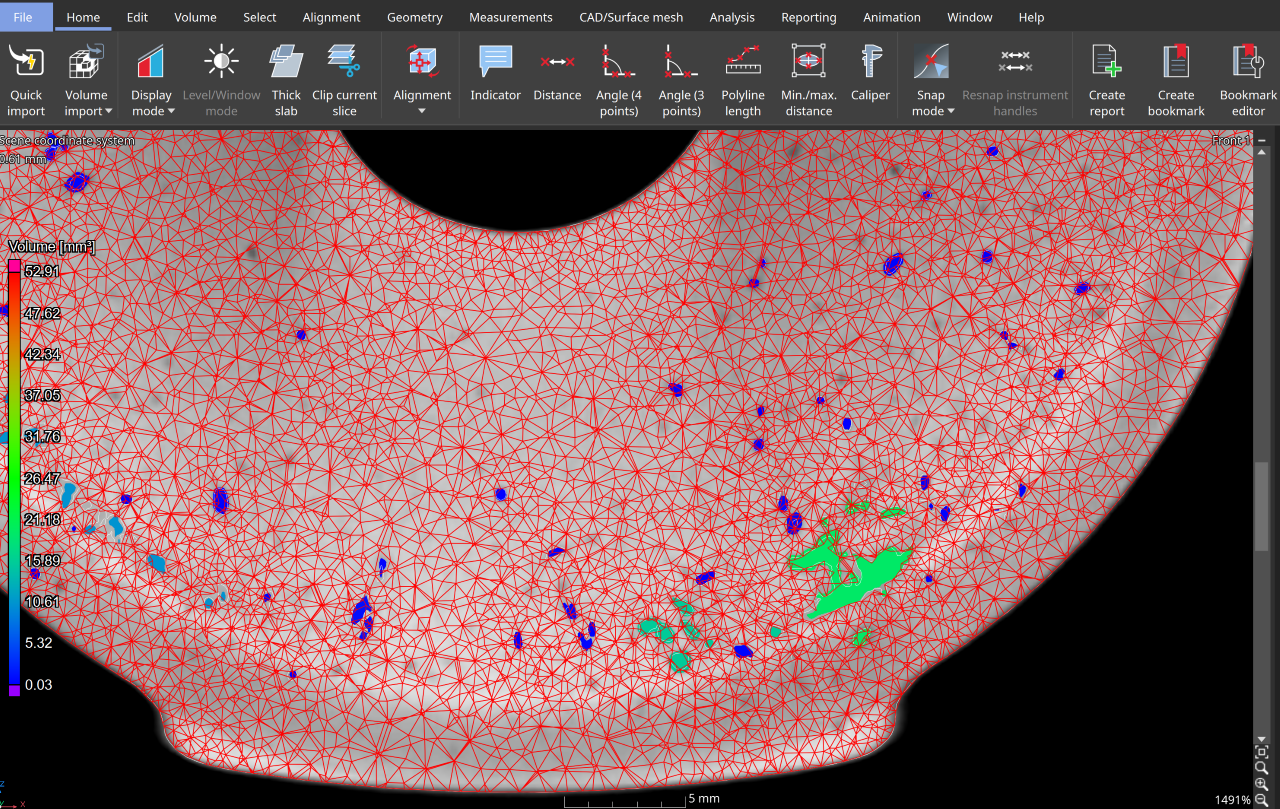

CT Scanning & Meshing

A CT scan is performed to inspect the part and to analyze the porosity in VGSTUDIO MAX. Afterward, a volume mesh is generated based on the CT scan with porosity mapped onto it. By doing so, a digital representation of the manufactured part with all its imperfections is generated.

NVH Simulation

Next, Romax is used to perform an NVH simulation on the digital twin. This procedure can be repeated for multiple prototypes and generates an understanding about the effect of the porosity and the resulting local stiffness variations on the NVH performance.

The simulation results, as well as the porosity information for multiple prototypes, are then fed into Odyssee to create a predictive interpolation model which can be applied to further porosity situations. Based on the outcomes, physically justified and functionally meaningful tolerance limits for porosity can be derived.

In Summary

NVH simulations use porosity data from a set of physical prototypes to ensure desired performance criteria are met without increasing unnecessary waste and production costs.

© 2025 Hexagon AB and/or its subsidiaries