CABINET VISION

Effectively design, price, render, and build with CABINET VISION

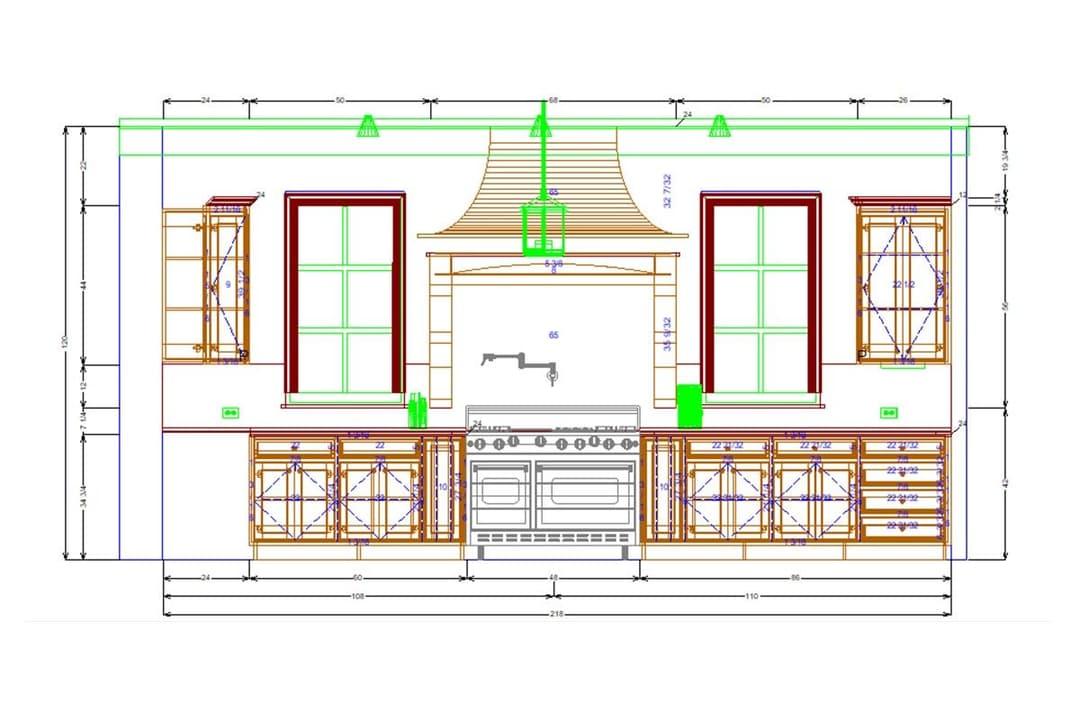

CABINET VISION is the most widely used design-for-manufacturing software, capable of custom cabinet and room design, photorealistic renderings, material optimization, bidding and costing, and cut lists and bill of materials. Combined with the powerful S2M CENTER, it can automatically create machine-ready G-Code for CNC flat table routers, point-to-point machines, panel saws, drill and dowel machines, chop saws, and other specialized CNC machinery.

Benefits And Features

The ultimate solution for custom case goods manufacturers

Sell more jobs

CABINET VISION is crafted to help you sell more jobs. It offers stunning presentations, seamless renderings, accurate pricing, and efficient bidding to win more projects and impress clients.

Create what you want

Unlock the full potential of your cabinetmaking creativity with our innovative design and manufacturing software, crafted to give you complete control in the design and engineering phases. Our solution empowers you to create exactly what you envision, with unparalleled flexibility and customization.

Produce more while reducing costs

Elevate your cabinetmaking operations with our state-of-the-art design and manufacturing software, designed to significantly increase productivity and output. Our comprehensive solution automates processes and enhances efficiency, enabling you to meet growing demands with ease.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2026 Hexagon AB and/or its subsidiaries