FASYS

Solution for factory automation

FASYS supports the entire manufacturing workflow, from conception to final product, by providing you with the relevant production information and securing the integration of all systems involved.

Benefits of FASYS include:

Benefits And Features

Efficient tool and operational resource management.

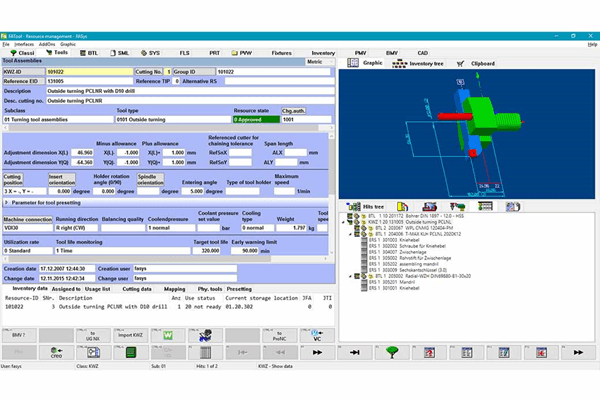

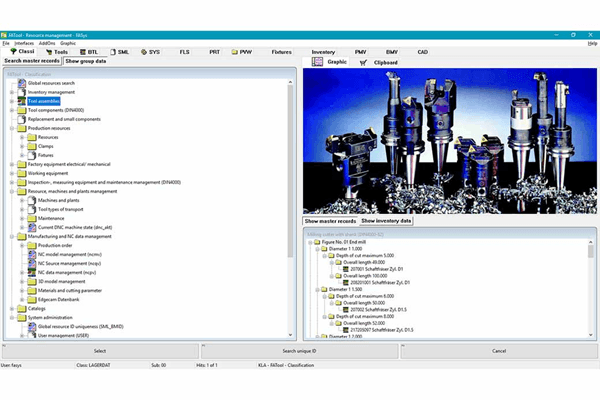

Centralized 3D Tool and Equipment Management

All production data is structured and managed centrally, ensuring quick access to relevant tool information in compliance with DIN 4000 standards. This streamlines tool assembly by defining connection conditions, reducing setup time, and improving tool utilization across production processes.

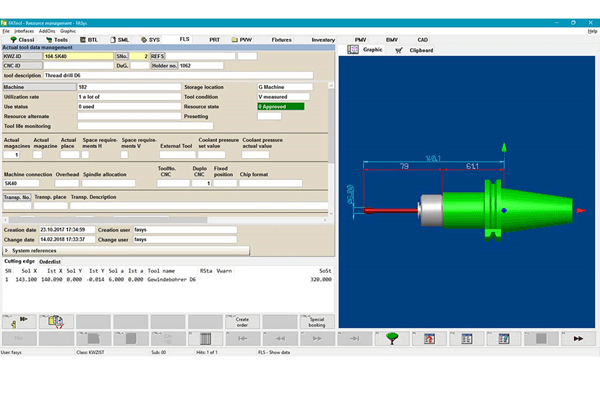

CAD/CAM Integration for Efficient Workflow

The direct CAD/CAM interface enables smooth data transfer between NC programming and tool management. By ensuring automatic file check-in/out and restricting simultaneous access, it minimizes errors, enhances collaboration, and accelerates the programming-to-production process.

Machine Connectivity and Resource Utilization

The DNC production client links multiple machines to a single PC, providing real-time access to job documents, NC programs, and setup sheets. This enhances efficiency by reducing downtime, improving document control, and enabling better coordination across production operations.

Training and Resources

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

Register today for full access to out download area and more.

| Version | Name | Date Released | File Size | |

|---|---|---|---|---|

| 2023.3 | FASYS | 2023-12-01 | -- | |

| 2024.2 | FASYS | 2024-10-01 | -- | |

| 2025.1 | FASYS | 2025-07-01 | -- |

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2026 Hexagon AB and/or its subsidiaries