© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

Automation for at- and inline scenarios

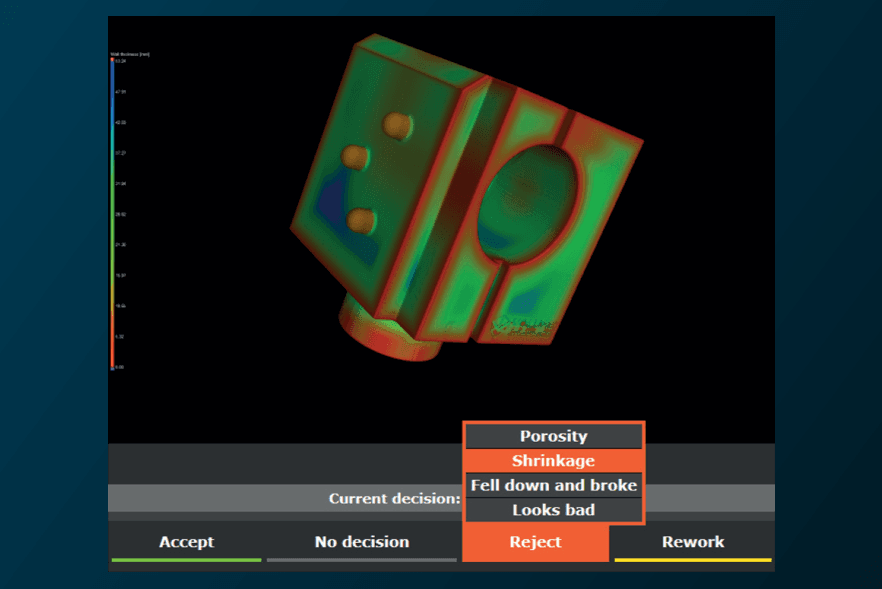

VGinLINE is your key to high-throughput, non-destructive quality control with minimal manual input. Designed to reduce human error and streamline inspection workflows, it enables real-time defect detection and fully autonomous quality monitoring.

Benefits And Features

Automatically inspect your parts in a non-destructive production environment

Effortless integration and complete control

VGinLINE offers a turnkey solution that integrates seamlessly into your production process with no programming required. This ensures an easy start to automation while maintaining complete control over your systems and data.

All files are archived unless instructed otherwise, enhancing accountability and security.

Reliable precision at the speed of production

Empower your inspection processes with VGinLINE’s robust capabilities. Whether utilizing classical methods or advanced deep-learning-based analyses, VGinLINE adapts to any inspection challenge.

Reference volumes calculated from manufactured parts classified as ‘good' act as solid reference points for all automated tasks.

Optimal workflow efficiency and adaptability

Enhance your operational efficiency by distributing inspection tasks across multiple workstations, mitigating the risk of individual system issues.

VGinLINE’s flexible inspection plan management allows for quick adaptation to process changes and new product introductions, ensuring your operations remain agile and responsive.

What's New

Exciting news: VG software 2025.4 is here

What’s New in VG software 2025.4

With version 2025.4 our software receives a number of new features and performance improvements to ease your daily work: After the recent redesign for the user-interface of the porosity/inclusion analysis, now there have been according to reworks for the wall thickness analyses in our software as well. Speaking of our porosity/inclusion analysis: There are now further customizable options available for the tolerancing and a new automatic "Threshold mode" has been added for the "Global threshold" approach that makes the analysis take into account the histogram of your current scan.

The new "Quick alignment" option gives an additional approach for performing your alignments that also works if the object you want to align covers only part of your reference object, or vice versa.

Furthermore, you can now add helpful descriptions to your views and the performance of the VGTRAINER has been improved to speed up the training of your segmentation models.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Automation for at- and inline scenarios

VGinLINE is your key to high-throughput, non-destructive quality control with minimal manual input. Designed to reduce human error and streamline inspection workflows, it enables real-time defect detection and fully autonomous quality monitoring.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

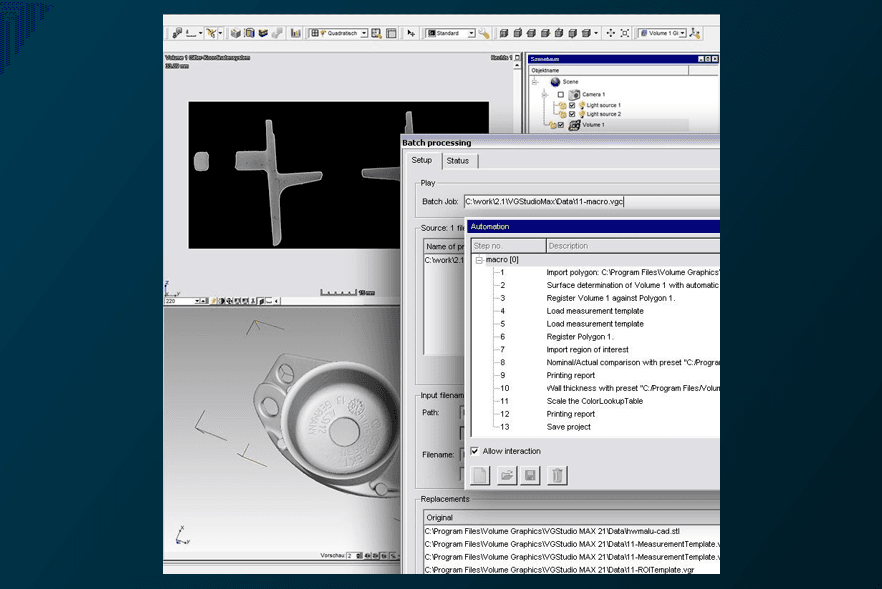

First, implement the inspection job (what is to be measured and analyzed) as a macro with the necessary steps in VGSTUDIO MAX. Then, create a job from the macro in VGSTUDIO MAX. This job then can be imported in VGinLINE.

A job consists of one or several macros plus all necessary information so that the task can be performed automatically (e.g., STLs and CAD files). Therefore, the job created in VGSTUDIO MAX can be easily used in VGinLINE.

VGinLINE can easily be scaled by adding new VGinLINE WORKERS/workstations to the system to enhance the overall performance and meet cycle time requirements.

VGinLINE CONTROLLER and VGinLINE WORKER are the core components of a VGinLINE system. With the VGinLINE CONTROLLER, the user imports or creates jobs and specifies the handling of data e.g., the input directory (data that needs to be analyzed) and output directory (destination of analyzed projects and/or reports). The VGinLINE WORKER is installed on each connected workstation. It executes the inspection jobs on the incoming data.