© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

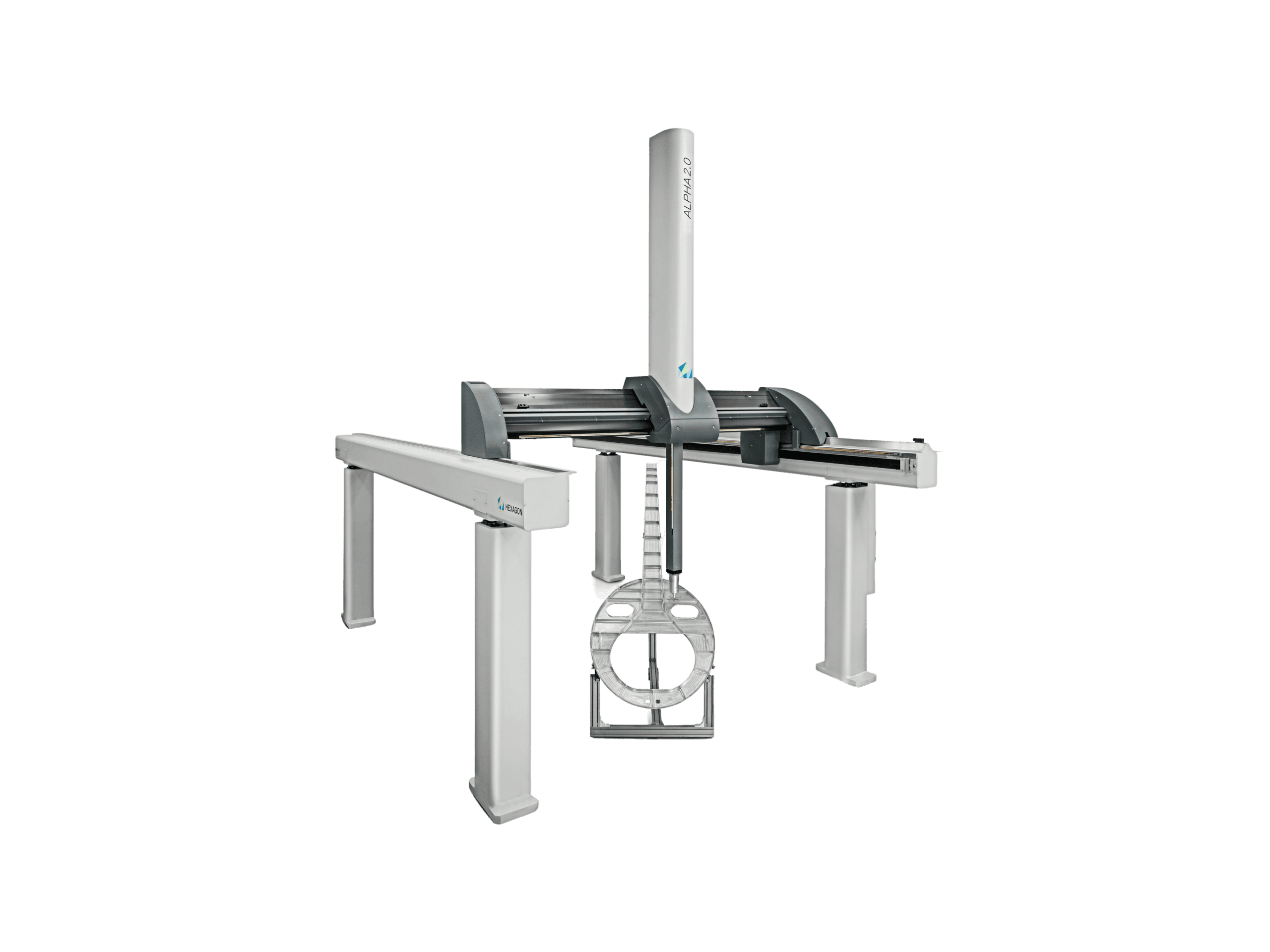

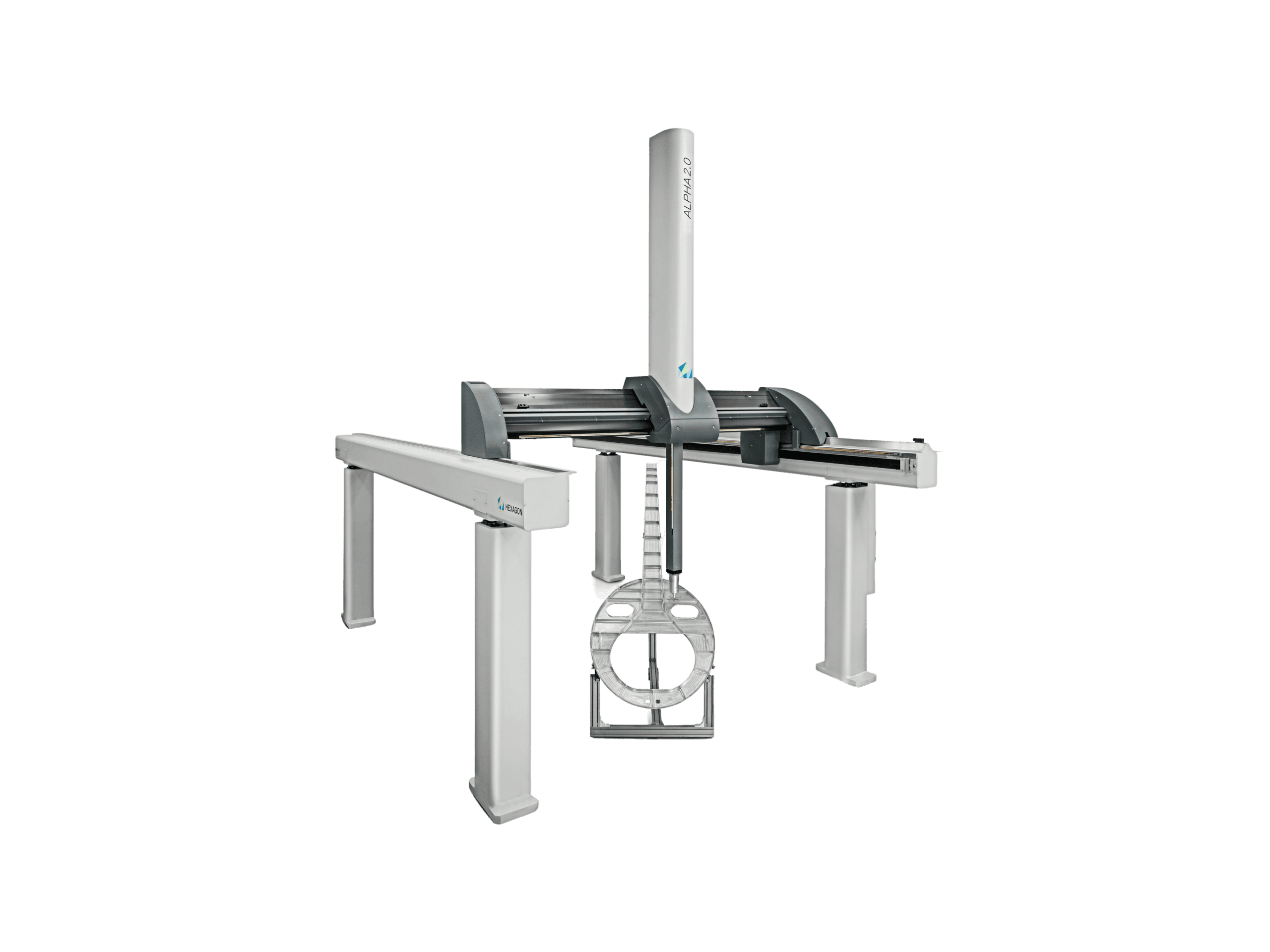

Flexible gantry coordinate measuring machine for large workpieces

ALPHA 2.0 Classic is a multi-purpose flexible CMM for the dimensional inspection of large castings and machined parts. When equipped with optical scanning sensors, the system can rapidly digitize millions of data points on freeform components. This makes it an ideal reverse engineering and inspection system for the die and mold manufacturing process.

ALPHA 2.0 Performance is a high-performance gantry CMM that, thanks to its high-rigidity silicon carbide ram and sophisticated multisensor temperature compensation, guarantees high accuracy and ease of use under all operating conditions.

Training and Resources

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Flexible gantry coordinate measuring machine for large workpieces

ALPHA 2.0 Classic is a multi-purpose flexible CMM for the dimensional inspection of large castings and machined parts. When equipped with optical scanning sensors, the system can rapidly digitize millions of data points on freeform components. This makes it an ideal reverse engineering and inspection system for the die and mold manufacturing process.

ALPHA 2.0 Performance is a high-performance gantry CMM that, thanks to its high-rigidity silicon carbide ram and sophisticated multisensor temperature compensation, guarantees high accuracy and ease of use under all operating conditions.

Evaluate your device's health with Eclipse Compass.

This tool reviews your hardware's status and usage, providing a clear score and actionable insights. Instantly find out if your device is ready, needs service, or requires an upgrade, enabling informed decisions and minimizing downtime.

ALPHA 2.0 Specifications

| Available Size (X, Y, Z) | |

|---|---|

20.33.10 / 20.33.15 / 20.50.15 / 25.33.15 / 25.50.15 / 25.33.18 / 25.50.18 | |

| Accuracy₂ | |

From 3.5μm + 3.5 L/1000, MPE(E0/E150)₁) [18-22 °C] From 3.5μm + 6.5 L/1000, MPE(E0/E150)₁) [16-26 °C] | |

| Probe type compatibility | |

Touch trigger probe Scanning probe Laser scanner probe | |

| Automation ready | |

YES | |

| Temperature specification | |

18 - 22 °C 16 - 26 °C |

₁ E0, MPE/E150, MPE specifications are to be formally understood as E0,MPE* /E150, MPE* for the case where non-normal CTE material calibrated test lengths are used.

₂ According to ISO 10360-2 (2009)

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

This product does not offer any software downloads.