© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

Bridging the gap between manufacturing and performance

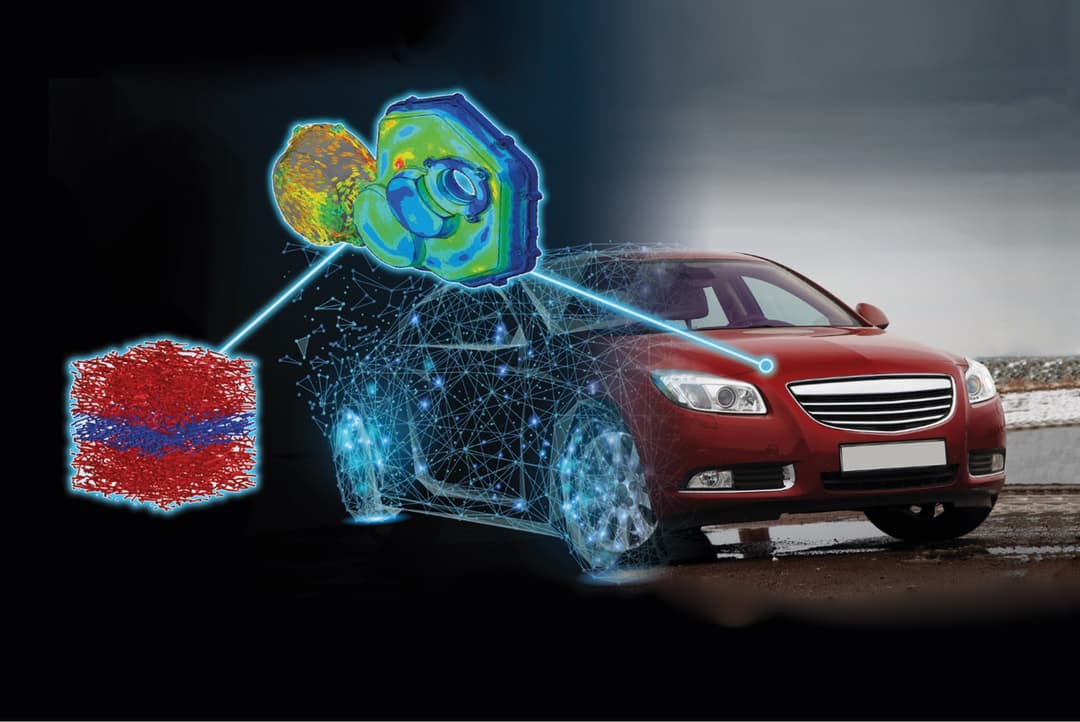

The Digimat solution, powered by ICME*, integrates materials across design & engineering, production and quality & inspection, resulting in lightweight designs with no compromise on performance or quality, while reducing both time-to-market and CO2 footprint.

*Integrated Computational Materials Engineering

Benefits And Features

Leverage materials to their fullest potential with Digimat’s material modelling software

Digital Materials Laboratory

Digimat's multiscale material simulations provide insights into microscopic mechanisms that influence macroscopic properties, enabling a precise understanding and accurate prediction of complex material behaviours. By creating digital twins of any material system, users can minimize the need for physical testing, optimize materials properties, and accelerate innovation.

Multiscale Simulations

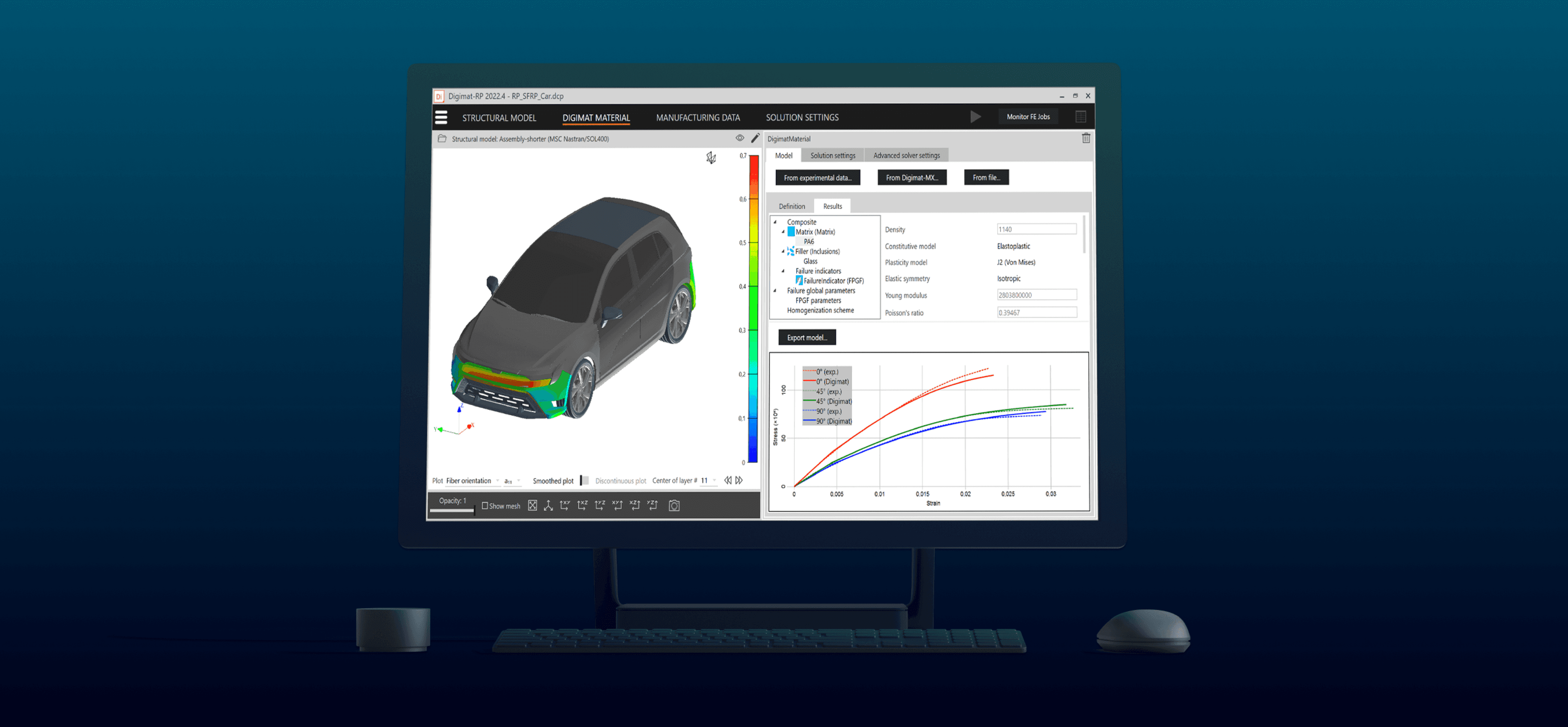

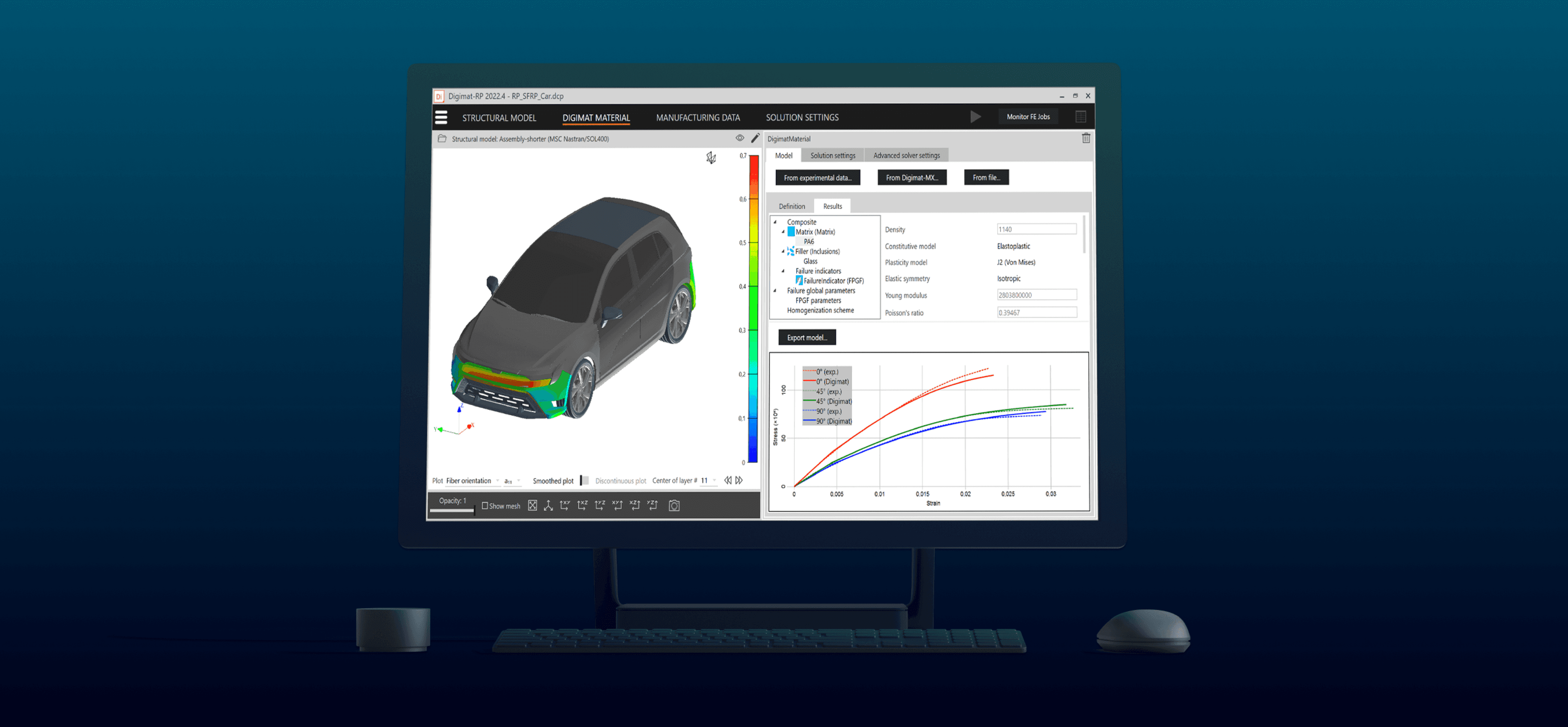

Powered by Integrated Computational Materials Engineering (ICME), Digimat intrinsically connects the manufacturing process, material properties, and structural part performance. By bridging the gap between manufacturing and structural performance, Digimat enriches CAE analyses, making design simulations more accurate and reliable. This approach unlocks lightweight designs without compromising performance or quality, while also reducing time-to-market and CO2 footprint.

Comprehensive Material Ecosystem

Digimat provides users with access to a unique material supplier ecosystem, offering high-fidelity material cards for CAE applications. This extensive database enables the design and validation of part performance across various loading scenarios. Additionally, Digimat facilitates easy and fast calibration of new material cards based on limited experimental data, allowing for efficient and reliable simulations.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Bridging the gap between manufacturing and performance

The Digimat solution, powered by ICME*, integrates materials across design & engineering, production and quality & inspection, resulting in lightweight designs with no compromise on performance or quality, while reducing both time-to-market and CO2 footprint.

*Integrated Computational Materials Engineering

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

Yes, it does. The easiest approach is setting up your reference analysis in Digimat-RP using the GUI. You can click on the submit button and export an RTF file when this is done.

This file can start the job in the command line in a DOS Command prompt, like:

C:\MSC.Software\Digimat\202X.Y\DigimatRP\exec\digimatRP.bat batch=on rpf=myFile.rpf log=myLog.txt.

More information is available on SimCompanion.

Digimat-FE can generate various types of foams: closed cell, open cells, and various topology: random, kelivn, and custom.

Digimat-MX is including data on 581 grades provided by 33 different material suppliers.

All Digimat solutions are available with the MSCOne token system at the exception of the fiber orientation estimator in Digimat-RP.

Digimat is supported on both Windows 10 and Linux Red Hat (7.9, 8.4), Suse (12 SP1, 12 SP2, 12 SP4, 15 SP1). Only the Digimat solvers are supported on Linux, not the Graphical User Interface.