© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

Utilize future-ready software that analyzes product accuracy

Effectively assess the precision and structural integrity of designs to ensure your final product meets important reliability, safety, and regulation requirements.

The benefits of using Dytran include:

Benefits And Features

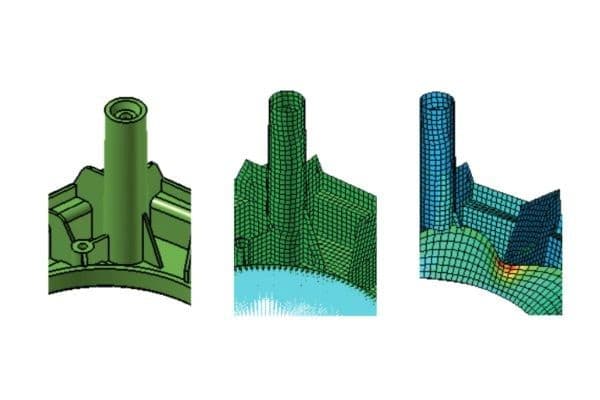

Assess the precision and structural integrity of designs that important reliability, safety, and regulation requirements

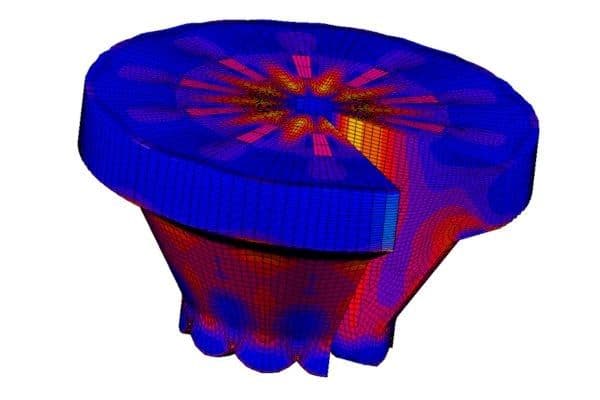

Understand dynamic nonlinear behavior

Simulate short-duration events such as impacts and crashes and analyze the complex nonlinear behavior of structural design elements.

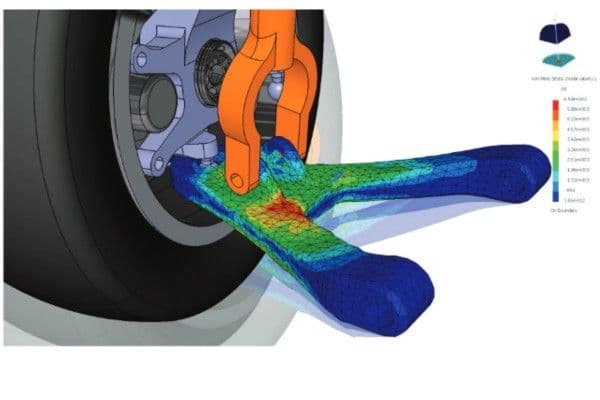

Ensure robust, safe designs

Effectively study the structural integrity of designs to ensure final products meet customer safety, reliability, and regulatory requirements.

Predict product performance

Accurately examine potential triggers for product failure and predict responses to real-world events.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Utilize future-ready software that analyzes product accuracy

Effectively assess the precision and structural integrity of designs to ensure your final product meets important reliability, safety, and regulation requirements.

The benefits of using Dytran include:

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

The output intervals can be controlled by using the TIMES and STEPS entries. Please see this article for details about how to use these entries. (SimCompanion Login Required)

Yes, we can do parallel processing in Dytran. Dytran has two options for parallel processing: SMP (Share Memory Parallel) and DMP (Distributed Memory Parallel). The details about both options can be found here. (SimCompanion Login Required)

To model fluid-structure interaction (FSI) in Dytran, you can use either the general coupling or fast-coupling methods. The fast-coupling method is more efficient and requires an orthogonal Euler mesh. Key steps include defining the Euler domain, creating a coupling surface, and setting up the necessary parameters for interaction. You can find a step-by-step example for the same here.

The choice between Lagrangian and Eulerian methods depends on the specific requirements of your simulation. If you need detailed particle tracking and are dealing with small to medium deformations, the Lagrangian approach might be more suitable. On the other hand, if you're working with fluid flow or structural parts where very large deformation is expected, the Eulerian method could be more efficient and suitable.