© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

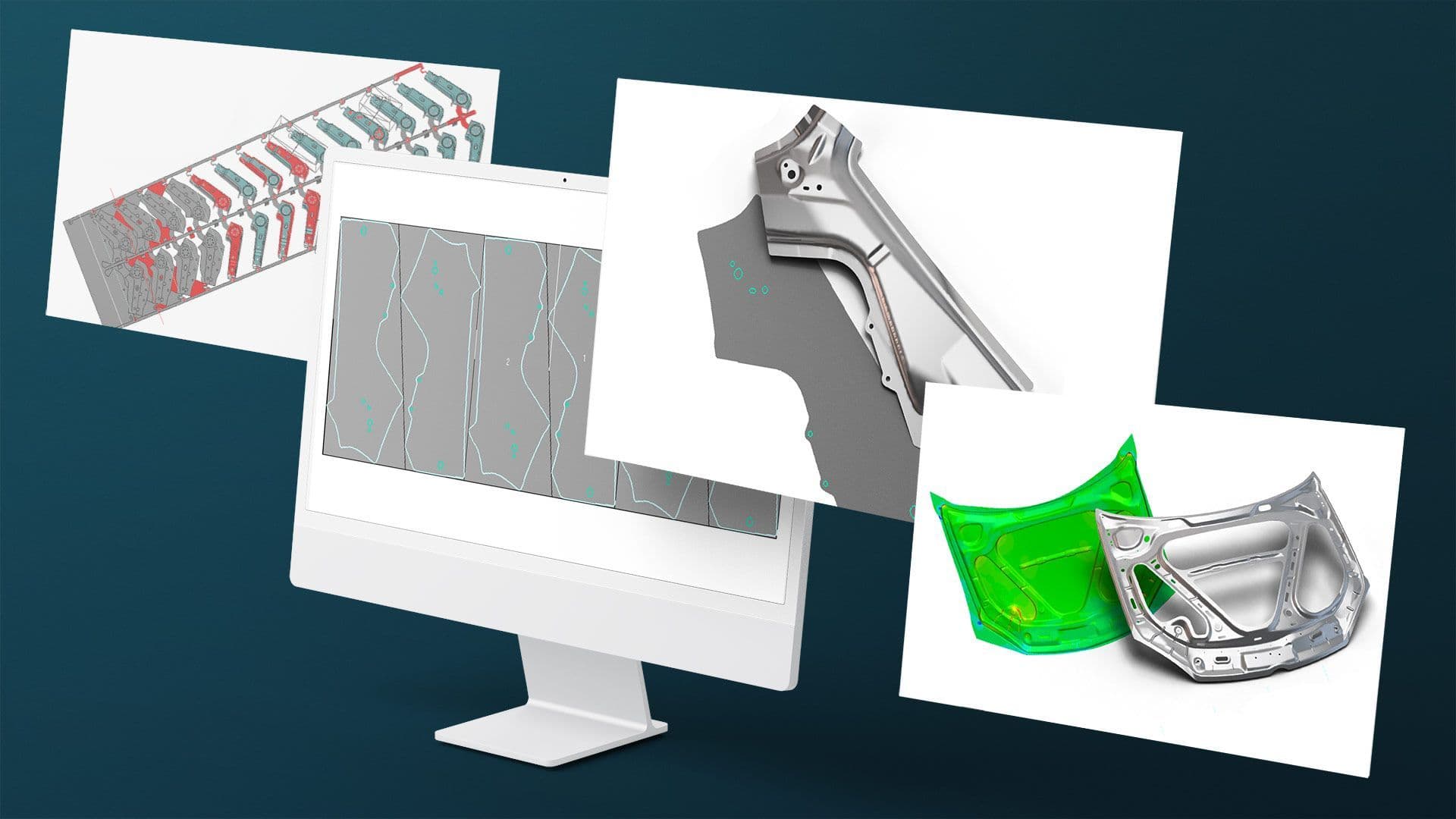

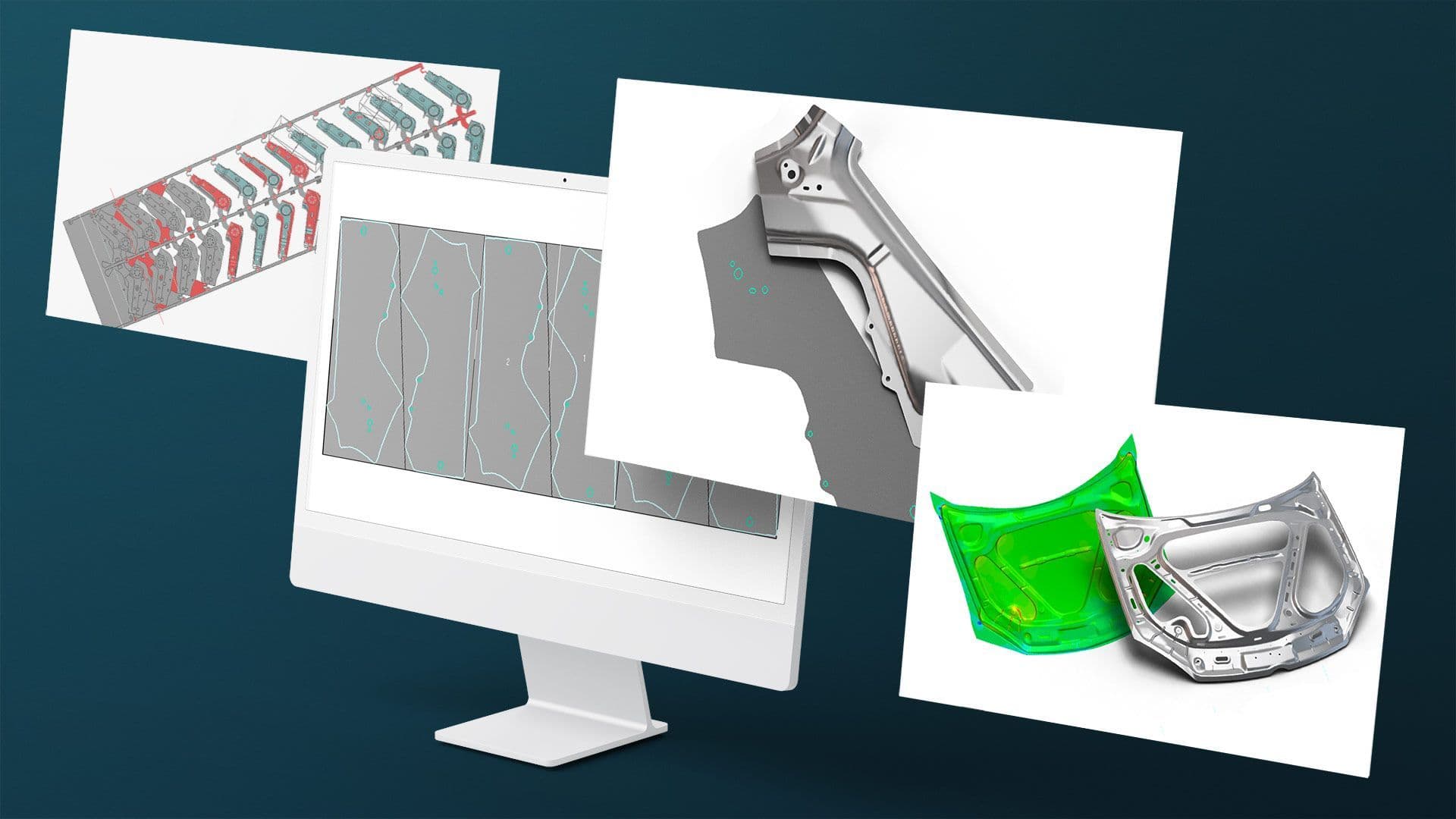

Cost engineering, process planning, and sheet metal simulation for progressive and line dies.

By combining the power of FTI’s premier formability analysis, blank development, and blank nesting software with specialized optimization tools, you can quickly and efficiently identify design changes that can reduce material and processing costs.

Benefits And Features

Optimize design, feasibility, and costing of sheet metal components and tooling

Cost Engineering

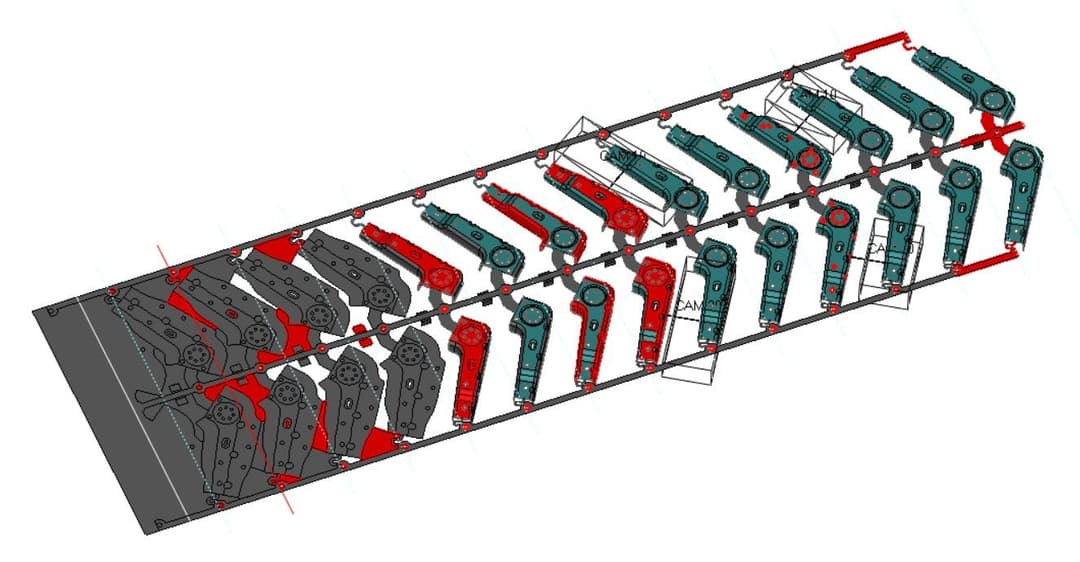

Establish and optimize target costs of pieces and tooling, with a detailed process plan for quoting, including high-quality images to detail die actions in each operation.

Early Feasibility

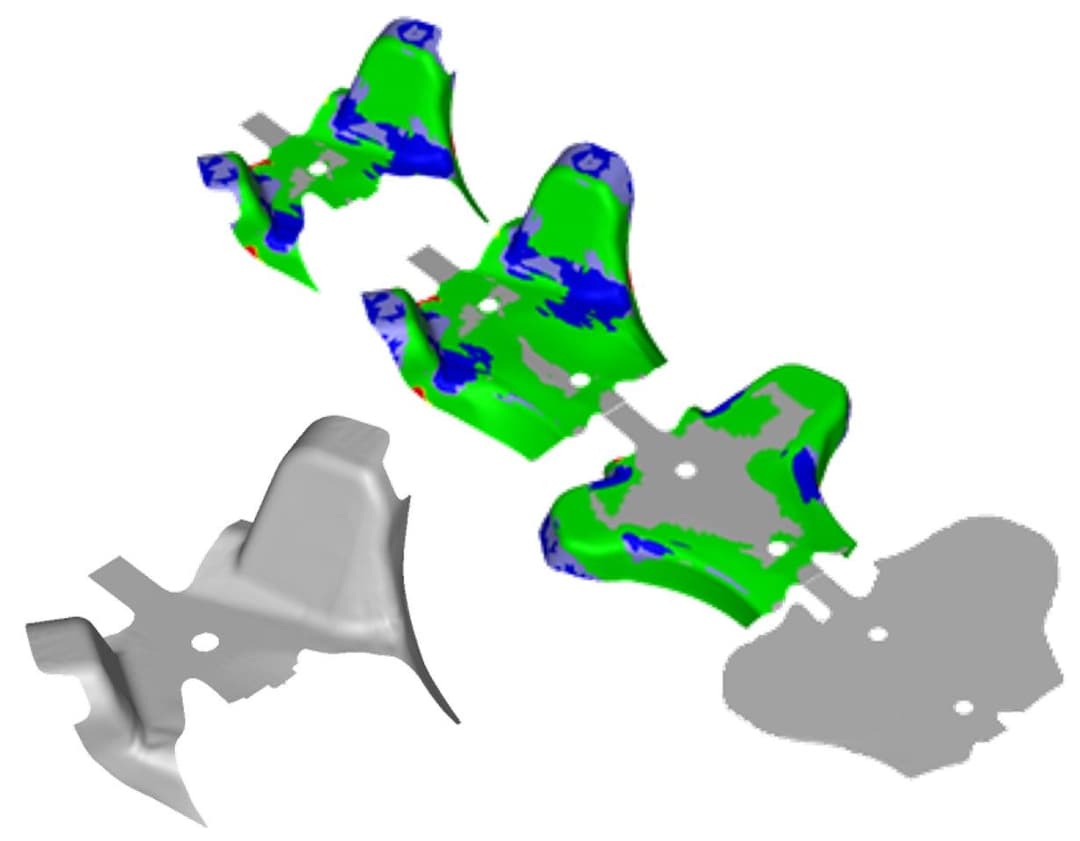

Accurately identify safety zone, FLD, material thinning, gathering conditions, major/minor strain, springback and provides compensation data.

Design Quality Products the First Time

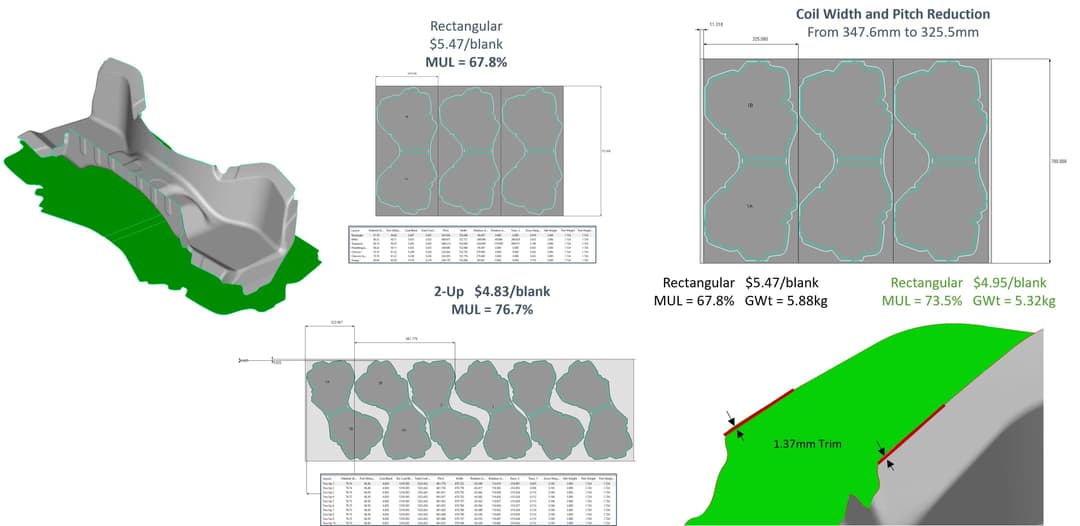

Identify product design changes that improve material utilization and reduce costs.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Cost engineering, process planning, and sheet metal simulation for progressive and line dies.

By combining the power of FTI’s premier formability analysis, blank development, and blank nesting software with specialized optimization tools, you can quickly and efficiently identify design changes that can reduce material and processing costs.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

This article explains how to resolve the error message "Programmatic access to Office VBA project is denied" or "Error 1004 - Programmatic access to the Visual Basic Project is not trusted" when creating reports from FTI FormingSuite.

FTI FormingSuite does work with MSCOne licensing. However, additional manual configuration steps are required. With a default installation, FTI FormingSuite will only look for a conventional FTI license. This article outlines the required steps.

FTI FormingSuite should not crash during opening, new project creation, closing projects or when displaying results. Slow graphics performance, model rotation and/or slow overall performance may also be caused by the same issue. This article will discuss how to remedy this issue.

This article outlines a number of potential solutions to problems starting an FTI license server for a floating FTI FormingSuite license.