© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

Advanced nonlinear simulation solutions

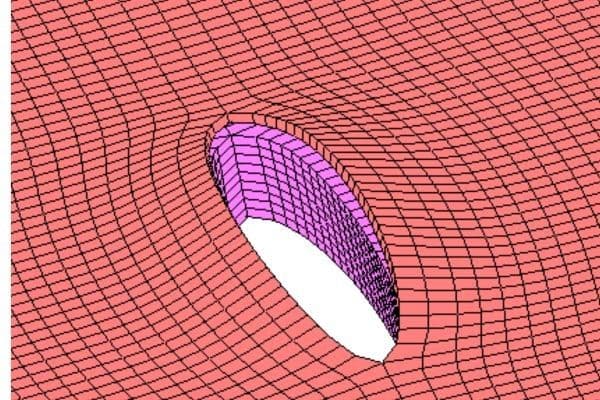

Marc is an advanced nonlinear multi-physics solver that enables you to predict the behavior of materials and prevent failures from occurring for complex structures in automotive, aerospace, high-tech and life sciences applications. Model nonlinear material behavior such as plasticity, hyper elasticity, and creep as well as contact and geometric nonlinearities.

Benefits And Features

Advanced nonlinear simulation solutions

Virtually test and validate product durability

Accurately predict design performance in nominal and/or severe environments with a robust nonlinear FEA solver.

Model complex nonlinear behavior

Model nonlinear material behavior such as plasticity, hyper elasticity, and creep as well as contact and geometric nonlinearities.

Ensure manufacturability

Capture manufacturing effects (sheet metal forming, forging, welding, machining, etc.) natively in the Marc solver or import them from other Hexagon software tools like Simufact and Digimat.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Advanced nonlinear simulation solutions

Marc is an advanced nonlinear multi-physics solver that enables you to predict the behavior of materials and prevent failures from occurring for complex structures in automotive, aerospace, high-tech and life sciences applications. Model nonlinear material behavior such as plasticity, hyper elasticity, and creep as well as contact and geometric nonlinearities.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

Marc offers contact MPC (Tying between touching and touched bodies) with the Marc offers contact MPC (tying between touching and touched bodies) with the Standard Node to Segment method. It also offers a penalty stiffness-based segment to segment contact algorithm. A combination of multi-point constraints (MPC) and nodal penalties is also available, which is known as Hybrid Node to Segment contact and is the recommended formulation for general use. Click here to learn more about Marc's contact capabilities.

It is engineering strain. For details about different experimental data fitting capabilities in Marc, please see this webinar.

Yes, it is! You will need to use the cut through element method to model this type of crack propagation. More details can be found here.

It requires defining the Farren and Taylor coefficient, applying a heat generation boundary condition, and activating it in the load case. More details can be found here.

There are many ways to close such initial gaps depending on how big they are and the root causes of them: stress-free node projection, contact body initial approach capability, body approach load case. Please review this webinar to learn more about these techniques and the associated pros and cons.