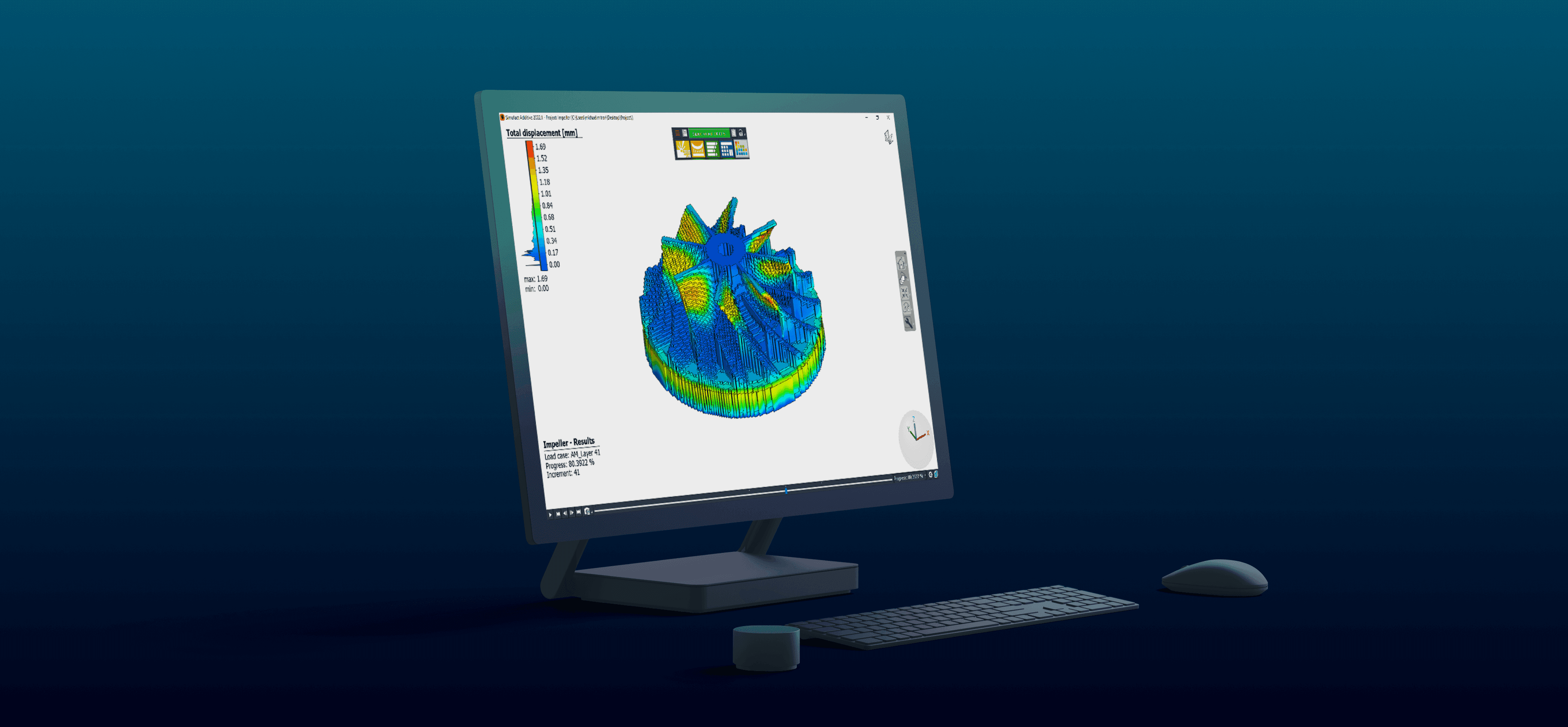

Simufact Additive

First-class solution for metal-based AM processes

Simufact Additive is a scalable software solution for the simulation of metal-based additive manufacturing processes which focuses on powder bed melting (L-PBF) and metal binder jetting (MBJ) processes. It is designed to predict and compensate for distortion, residual stress and temperature distribution throughout the printing, heat treatment, cutting, hot isostatic pressing (HIP) as well as machining processes virtually before the part is manufactured by the 3D metal printer in reality.

Benefits And Features

Print 3D metal AM parts right first-time with Simufact Additive

Simufact Additive: Master your metal prints

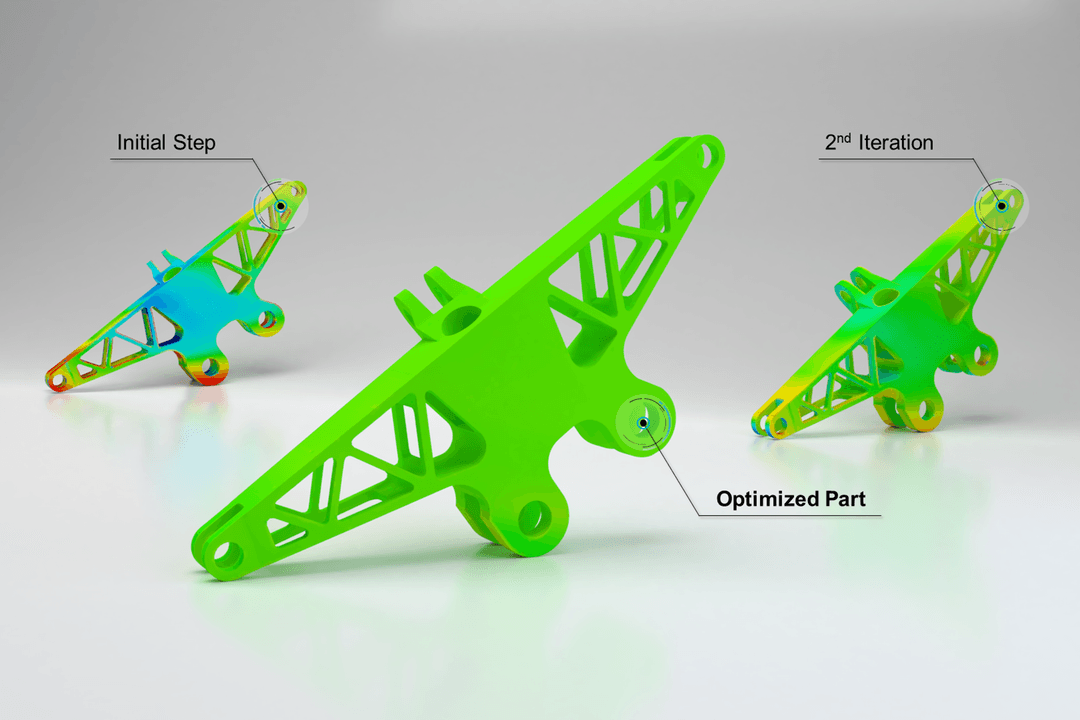

Simufact Additive provides powerful simulation tools to predict and correct issues in metal additive manufacturing: From LPBF, sintering to machining. By accurately modeling thermal and mechanical behaviours, it helps you optimise designs, reduce distortions, and ensure high-quality, reliable parts right from the first print.

Print Smart! Optimise with Simufact Additive

This powerful solution enables efficient additive manufacturing by simulating the entire process, from production to machining and heat treatment. It identifies potential issues like stress and deformation early, allowing you to make informed adjustments to your parameters, saving time and reducing material waste.

Capture defects and perfect your prints, every time

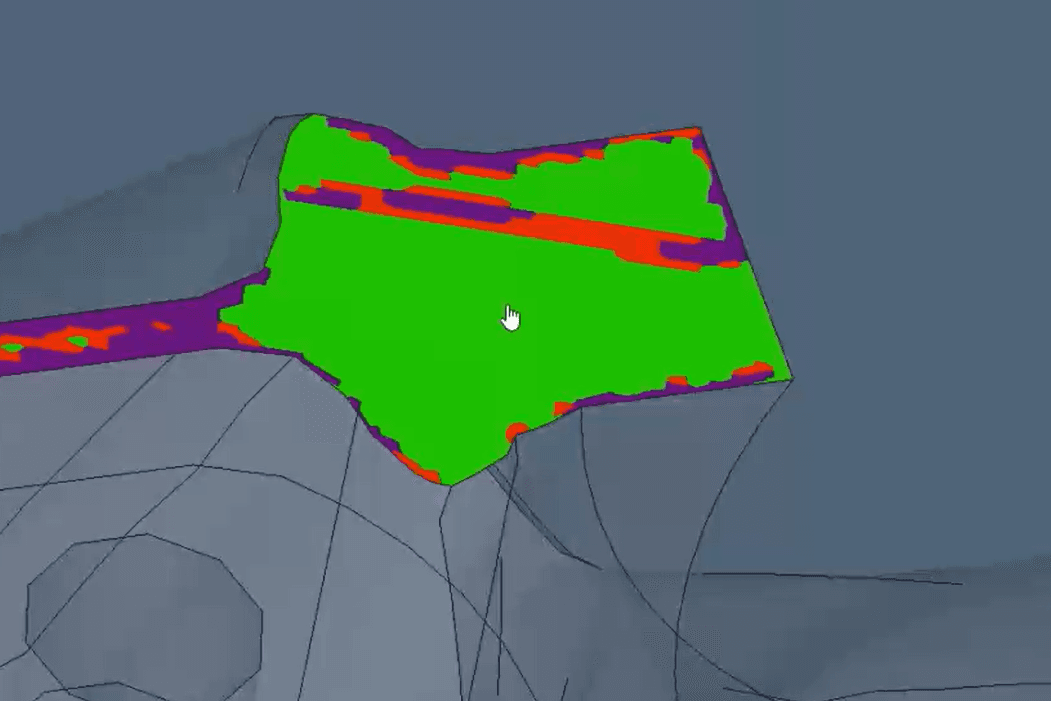

Enhance your AM precision with the PBF Process and Defect Analysis (PDA) module. Anticipate and resolve common issues like warping, residual stress, and defects such as porosity and incomplete fusion. By leveraging PDA's advanced capabilities, you can optimise parameters and significantly reduce trial-and-error, ensuring each metal part meets its exact specifications.

Training and Resources

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

Please see this article for more information.

This message appears when the surface mesh uses a large element size compared to the voxel mesh. The good news is that you can generate a new surface mesh even after the simulation results are present. After a new mesh is created, the result values are mapped onto the surface mesh.As a rule of thumb, the surface mesh should have the same edge length as the voxel mesh. The surface mesh is created in the analysis widget.

Simufact Additive does not offer an option to be controlled from outside (like e.g. Marc Mentat does with py_connect). There are two ways to work around this:

1) Rework your workflow to control everything by the Python script running inside Simufact Additive.

2) Use your outside control script to create a temporary script with the commands for Simufact Additive and use ...\simufact\additive\<version>\bin\runscript.bat to start Simufact Additive when running this script.

The workflow consists of - volume meshing - export of a t16 file- optional change of the unit system used - taking care of the material properties which are described in this article.

If only the result geometry needs to be transferred, there are additional, simpler options.

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2025 Hexagon AB and/or its subsidiaries