Multi-attribute design and optimizations

Simulation tools dedicated to gearbox applications, from rapid layout investigations to optimization for efficiency, durability and NVH, and democratized links to CFD, acoustics and more.

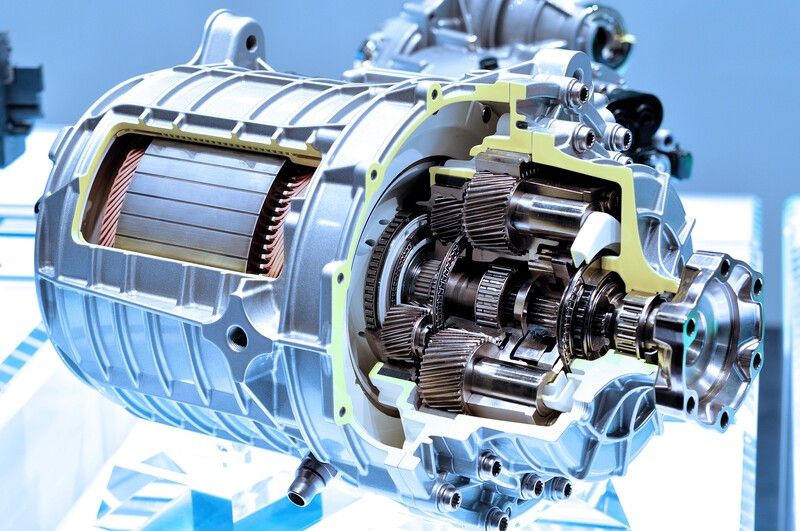

Designing gearboxes for EVs presents new challenges. These include higher speeds and frequencies, the need to increase range by improving efficiency, reducing weight, and increasing power density, and the requirement to bring products to market quickly, with reduced physical testing.

At the initial concept stage, designers must find the optimum layout from thousands of architectural possibilities whilst understanding performance potential to guide engineering decisions and enable innovation with fewer risks.

As the design develops, engineers need to be confident that it will satisfy requirements in durability (life and maximum load), NVH (a critical part of customer experience, with no engine to mask annoying noises), and efficiency (minimizing component losses and managing thermal effects). Our multi-attribute design and optimization solution enables engineers to make decisions about trade-offs between these conflicting attributes whilst also understanding the impact of manufacturing processes and variability. This creates an iterative and efficient CAE-led design process that brings together simulation and manufacturing and reduces physical prototyping.

Design durable, efficient, and quiet EV gearboxes. Rapid simulations provide engineering insights into component performance and the system-level impact of design decisions, reducing physical prototyping.

Our approach

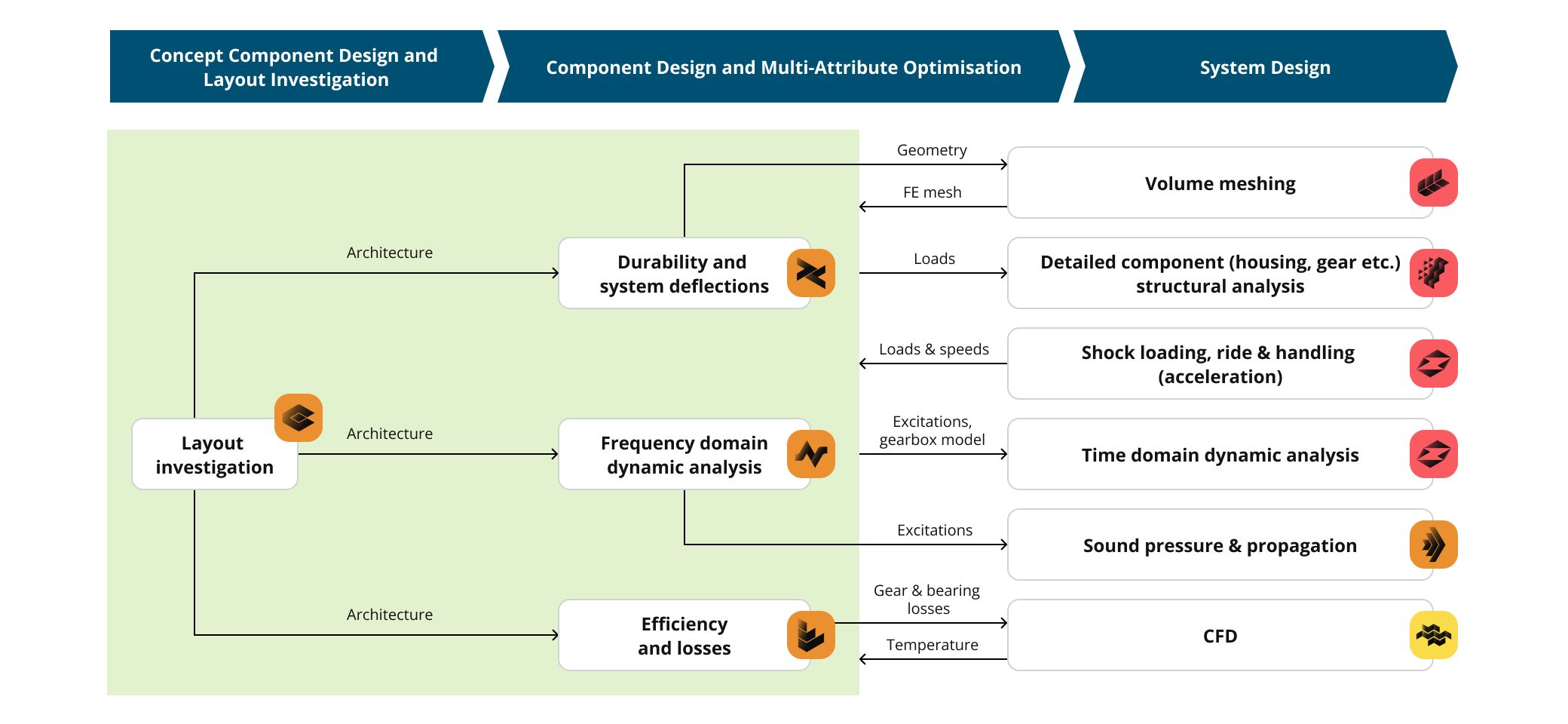

Concept component design and layout investigation

Beginning from the early design stages, Romax Concept enables rapid build and analysis of multiple gearbox architectures, to explore the design space and make good engineering decisions based on insight. With confidence that the design will meet requirements from an early stage, engineers can adopt a CAE-led design process to decrease development time and reduce the risk of having to make significant and costly design changes later on.

Component design and multi-attribute optimization

Once the layout is decided, trusted and validated best-in-class tools Romax Enduro, Romax Spectrum, and Romax Energy can be used (either independently or as part of an integrated suite) for detailed gearbox design and multi-attribute optimization, balancing NVH, efficiency, and durability performance.

Detailed system design and full drivetrain integration

As the design matures, the following tools can be used:

- MSC Nastran for detailed component structural analysis

- Actran for detailed noise analysis and propagation in the vehicle

- Adams for time domain dynamic analysis as well as shock loading and handling optimization

- Cradle for CFD and thermal management

Create effective optimization processes

With constant feedback loops between the tools, you can achieve an iterative CAE-led design process. This allows teams to make effective design changes, improving whole system performance as well as bringing together simulation and manufacturing to ensure that the as-manufactured product will behave like the as-designed.

In Summary

Multi-attribute design and optimization creates an iterative and efficient CAE-led design process that brings together simulation and manufacturing and reduces physical prototyping.

Products

© 2025 Hexagon AB and/or its subsidiaries