NCSIMUL

Maximize your machine productivity with a Digital Twin

Directly enhance the quality of machining operations to reduce manufacturing costs, decrease setup times, and eliminate all programming errors. NCSIMUL is the Universal Digital Twin Certification & Optimization solution to guarantee a 100% crash/edit free machine code. NCSIMUL is CAM and CNC machine agnostic.

The benefits of using NCSIMUL include:

Benefits And Features

G-code certification, optimization & documentation for CNC machining.

G-code verification

G-code verification includes a full CNC program and macro decoding and validation with automatic programming error detection, interactive tool path tracing, interactive machine display, and delivers the accurate machining cycle time.

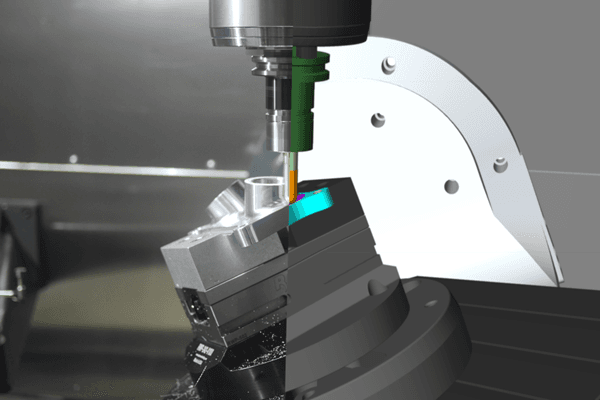

Full machine simulation

The Digital Twin machines provide realistic simulation and material cutting, detecting errors and collisions before machining (such as rapid motions in material, machining with spindle stopped or cutting over the flute length). CNC simulation includes probe devices macro, tool changes and machine accessories.

Certification automation

Checking 100% of program modifications is critical, as one simple modification can cause severe damages to a CNC machine. Certification and Optimization started with just a few clicks, will end with a completed report notification, while other programming or production tasks are performed.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2026 Hexagon AB and/or its subsidiaries