© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

Enabling superior understanding of bearing behavior for informed, independent bearing design and selection

Romax Spin provides bearing designers and application engineers with the insight to design and select bearings for optimum performance and durability as part of a whole system model. The benefits of using Romax Spin include:

Benefits And Features

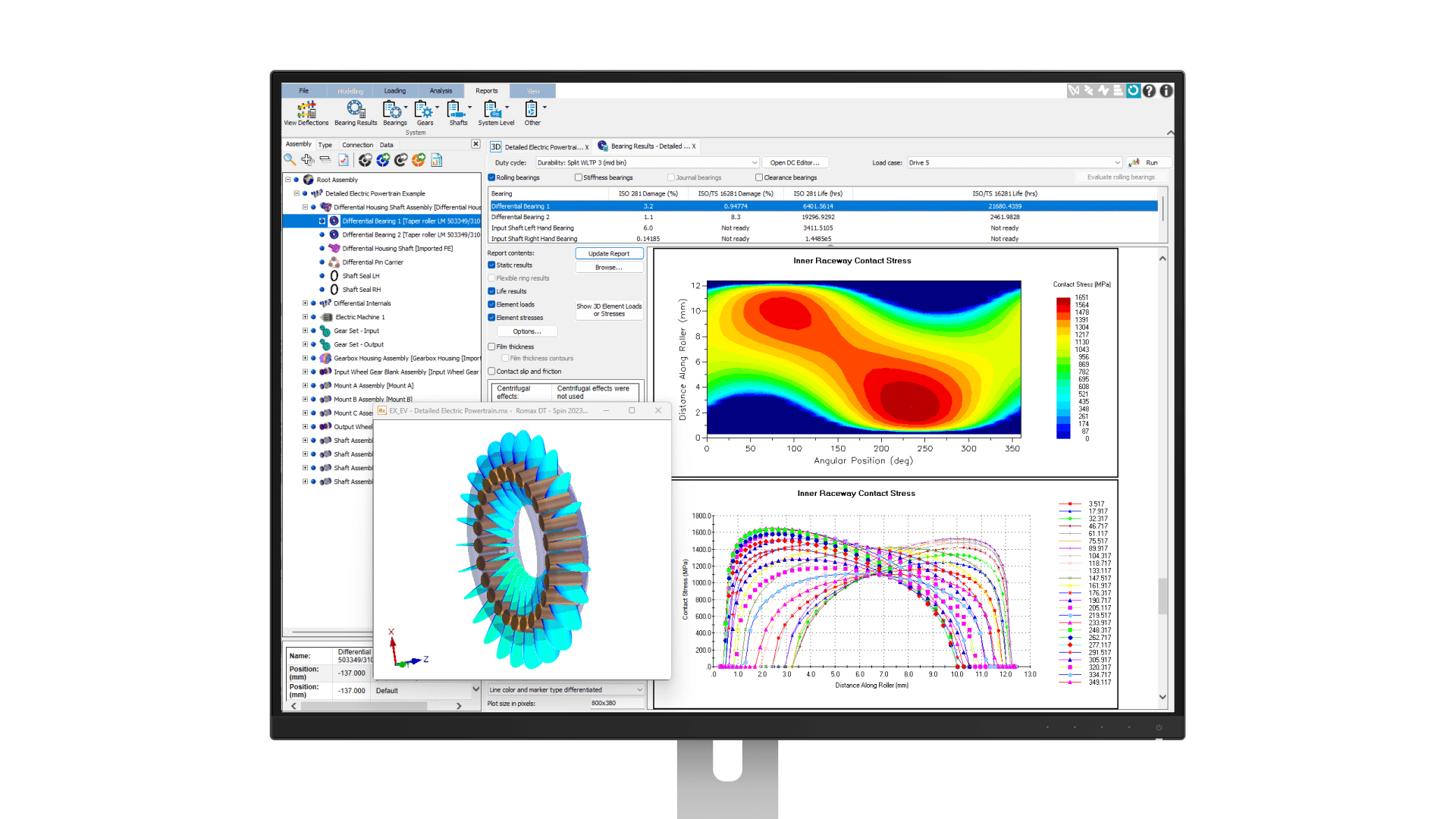

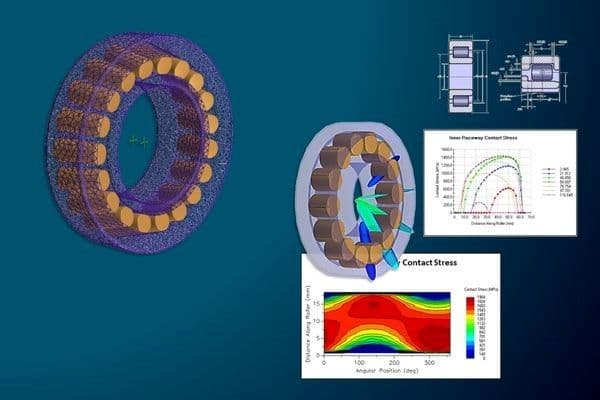

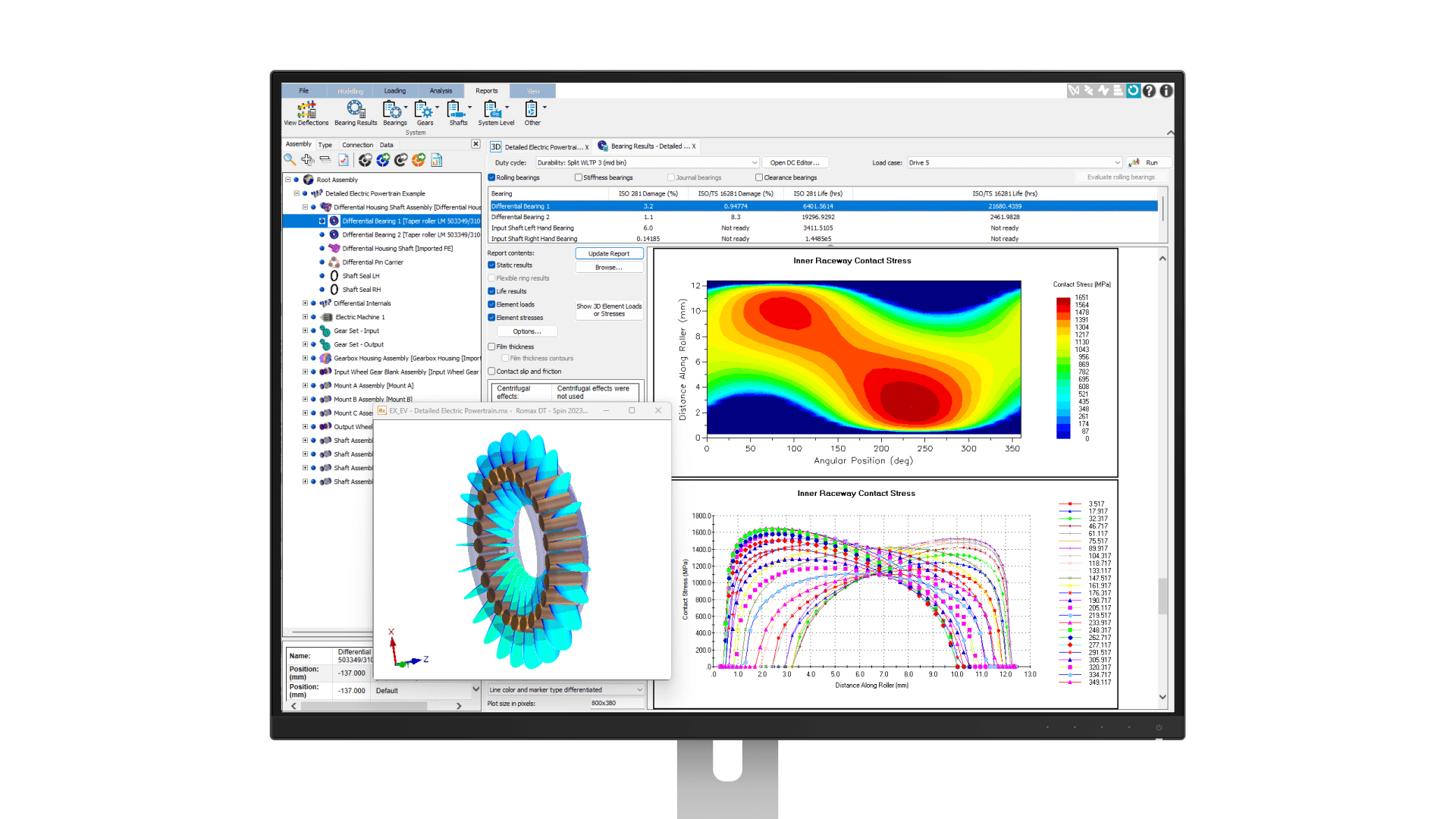

Cutting-edge rolling element bearing analysis as part of a full electromechanical system

Improved collaboration

Access more than 60,000 bearings from SKF, Schaeffler, Timken, JTEKT, and Nachi, or model fully customizable bearings and specify assembly and operating properties.

Application optimization

Accurately predict element and raceway stresses, rib contact, edge stress, roller contact analysis, and contact truncation, considering full system deflection, load analysis, and bearing misalignments.

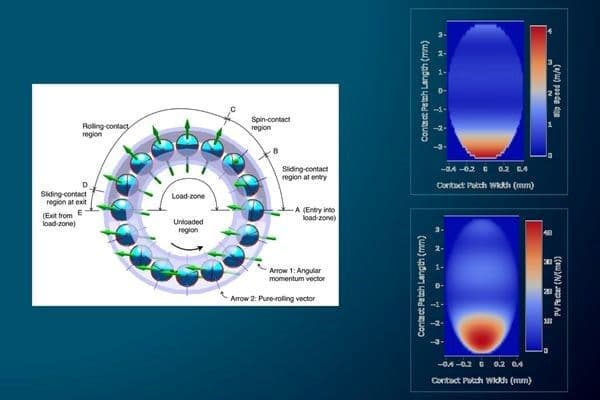

Unrivaled insight

Time-domain simulation to analyze dynamic behavior and avoid novel failure modes such as skidding.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Enabling superior understanding of bearing behavior for informed, independent bearing design and selection

Romax Spin provides bearing designers and application engineers with the insight to design and select bearings for optimum performance and durability as part of a whole system model. The benefits of using Romax Spin include:

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

Spin is a commercial tool with a proven track record, superior usability, reliable support, and updates. It is much faster and easier to use than FEA and is much more scalable and efficient than internal tools and general-purpose FEA.

Bearings are critical for the operation of rotating machinery, and it’s important to have in-house analysis capabilities to make sound engineering decisions and supplier choices. Spin allows suppliers to share data securely using proprietary bearing catalogs so that analyses take into account all relevant details while protecting the creator's IP.

We recommend you follow our tutorial packs. The link to the latest tutorials can be found on the Romax Support Homepage.

Detailed Technotes on all new features are available on the PDC. You can find the Latest documentation link on the Romax Support Homepage.

Please see here.

Please see here.

Please see here.

Please see here.