© 2026 Hexagon AB and/or its subsidiaries

© 2026 Hexagon AB and/or its subsidiaries

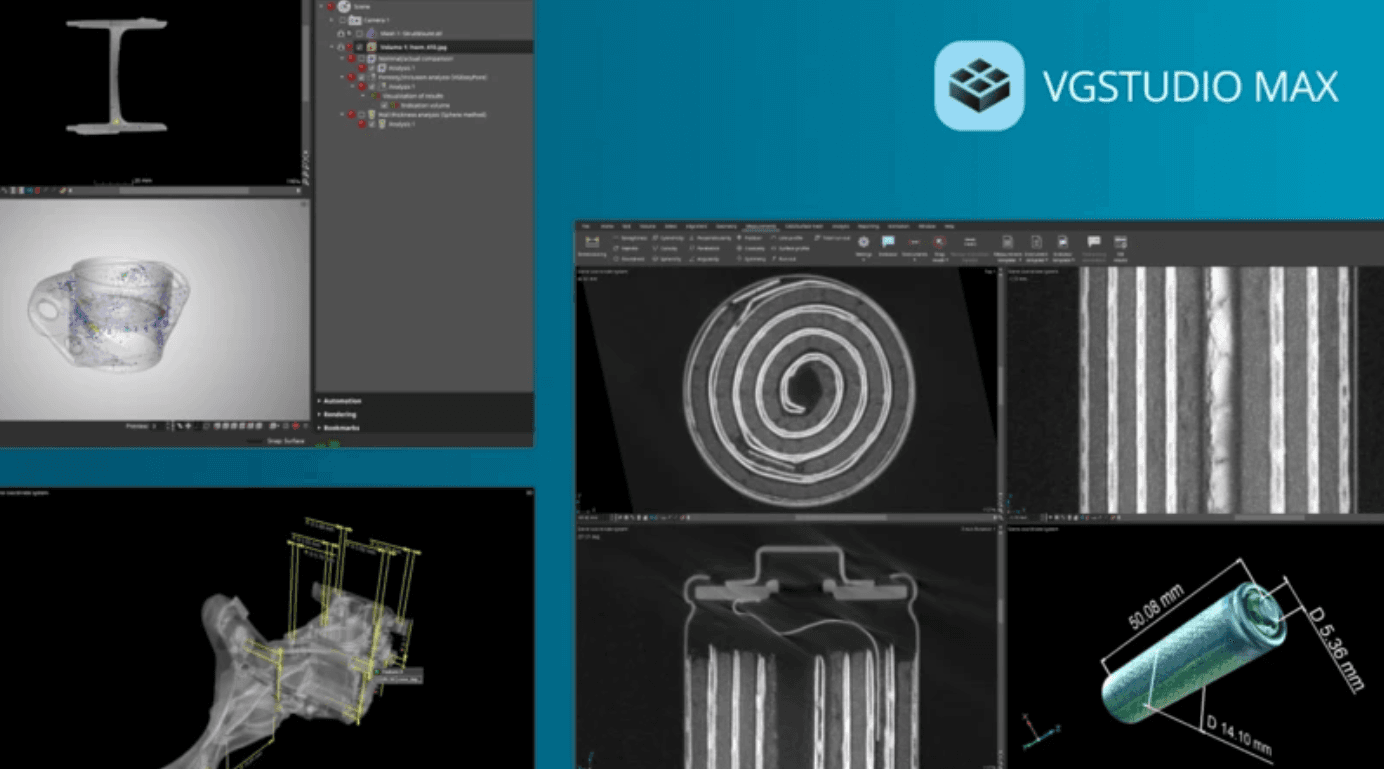

Versatile, industry-leading software for the holistic analysis and visualization of industrial CT and NDT data.

VGSTUDIO MAX delivers non-destructive insights at every stage of the product lifecycle, helping manufacturers improve quality, reduce costs, and accelerate production. It's the go-to software for precision-driven industries with a full spectrum of inspection tools, from CT reconstruction and AI-based segmentation to GD&T, material analysis, and simulation.

Benefits And Features

Lead in quality while saving time and money with the industry's first and longest-trusted software for CT analysis and non-destructive evaluation (NDE)

Drive product development and quality with unmatched insights

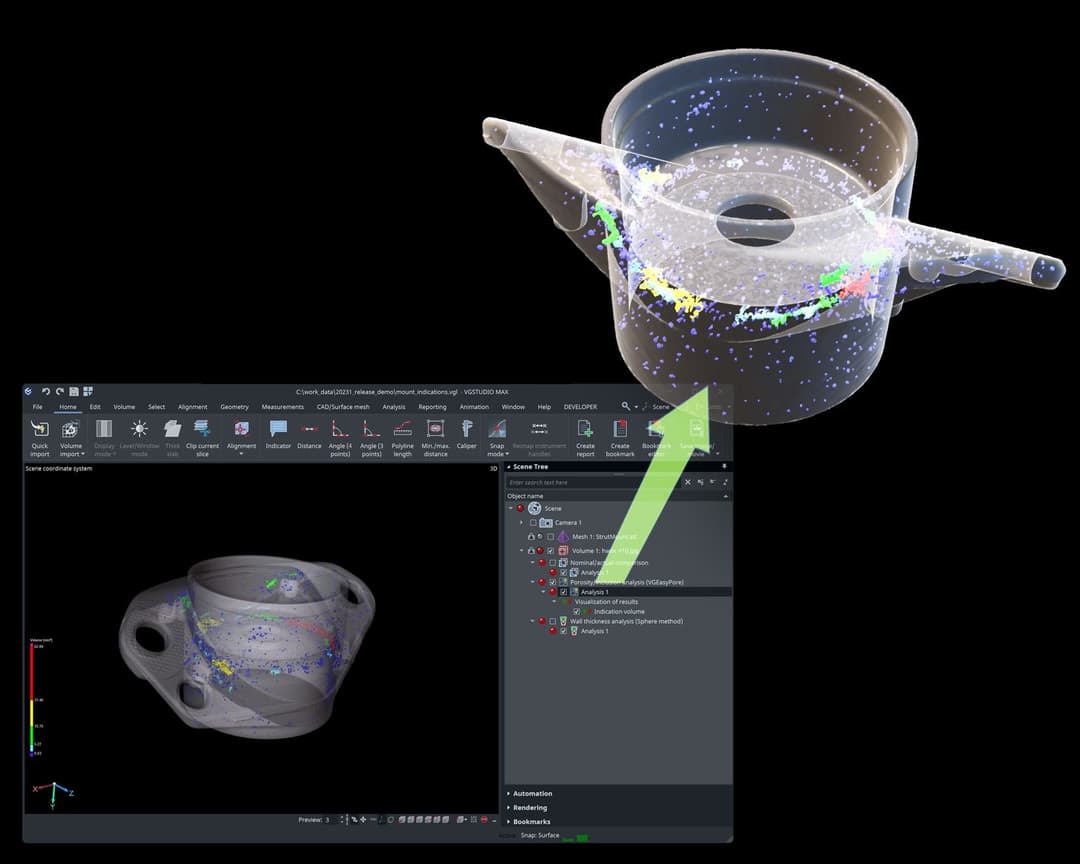

VGSTUDIO MAX empowers you to swiftly move your products from concept to reality with its full suite of CT analysis tools. Whether you're testing simple or complex parts, in the metrology lab or on the shop floor, VGSTUDIO MAX is the de facto standard for the reliable detection of critical defects.

Proven in industrial practice for over 25 years, VGSTUDIO MAX has passed NIST, ISO, and PTB standards.

Enhance quality inspection with advanced analysis and AI-driven precision

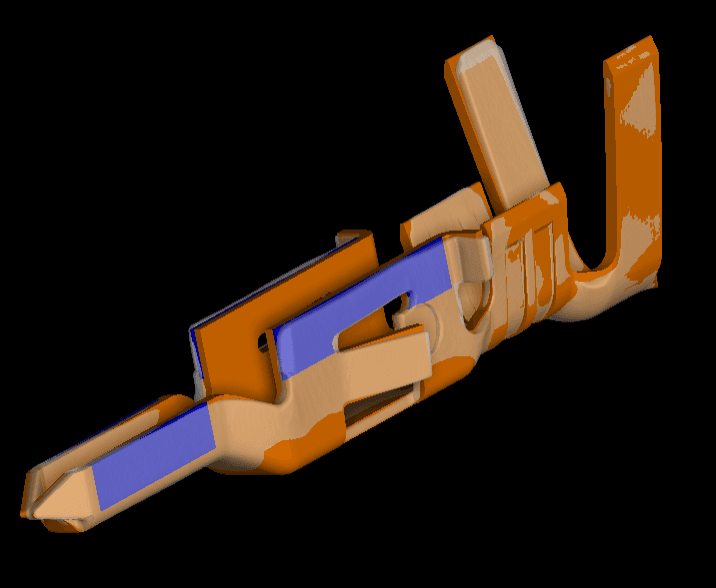

Elevate your quality inspection processes with VGSTUDIO MAX’s versatile toolset. Utilize geometry and material analyses to detect and characterize defects and perform simulations to assess performance under stress.

The integration of AI-based solutions enables smart, autonomous data segmentation, ensuring precise and efficient analysis that leads to better-informed decisions and superior product quality.

Outpace with advanced and next-generation NDE technology

Experience the confidence of using cutting-edge tools that evolve with your needs. VGSTUDIO MAX continuously updates to tackle industry challenges and supports a wide range of data types, ensuring you remain at the forefront of innovation.

Its scalable design allows you to automate processes and expand functionality as your inspection requirements grow.

What's New

Exciting news: VG software 2025.4 is here

What’s New in VG software 2025.4

With version 2025.4 our software receives a number of new features and performance improvements to ease your daily work: After the recent redesign for the user-interface of the porosity/inclusion analysis, now there have been according to reworks for the wall thickness analyses in our software as well. Speaking of our porosity/inclusion analysis: There are now further customizable options available for the tolerancing and a new automatic "Threshold mode" has been added for the "Global threshold" approach that makes the analysis take into account the histogram of your current scan.

The new "Quick alignment" option gives an additional approach for performing your alignments that also works if the object you want to align covers only part of your reference object, or vice versa.

Furthermore, you can now add helpful descriptions to your views and the performance of the VGTRAINER has been improved to speed up the training of your segmentation models.

Training and Resources

Connect and collaborate with your peers and experts

The Nexus Community provides you with excellent peer forums and the opportunity to learn from thousands of others in your industry. Currently, hundreds of peer forums waiting for you to explore into. Discover best practices and get the answers you need to succeed. Register for Nexus to get full access the Community forums.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

Versatile, industry-leading software for the holistic analysis and visualization of industrial CT and NDT data.

VGSTUDIO MAX delivers non-destructive insights at every stage of the product lifecycle, helping manufacturers improve quality, reduce costs, and accelerate production. It's the go-to software for precision-driven industries with a full spectrum of inspection tools, from CT reconstruction and AI-based segmentation to GD&T, material analysis, and simulation.

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Expand your knowledge

Our Knowledge Base is your go-to hub for in-depth insights and valuable information. Explore a rich collection of articles and detailed white papers crafted to provide you with the knowledge you need to excel. From industry trends to expert analyses, our Knowledge Base is designed to keep you informed and empowered with the latest and most relevant content.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

Get the most out of our resources.

For the latest updates, resources, and software, please visit our Download Center

Click the link to access the files you need today

Frequently Asked Questions

You have two options: Simple and fast via the instruments, or detailed, precise, and compliant with standards via the functionalities of the Coordinate Measurement module.

Find more information in the corresponding tutorials in VGSTUDIO MAX. To open them, click Help > Show tutorials > Geometry Analysis > Coordinate Measurement – Introduction and Coordinate Measurement - Advanced.

When pores still are not found activate the option Preview. This helps to analyze which settings must be adapted. To reduce time this approach could be performed on a small representative ROI.

Find more information in the corresponding tutorial in VGSTUDIO MAX. To open it, click Help > Show tutorials > Material Analysis > Porosity/Inclusion Analysis.

First, completely set up the analysis in VGSTUDIO MAX and export it as an evaluation. Then, import the evaluation when reporting the macro at the appropriate time when the analysis is to be calculated.

Find more information in the corresponding tutorial in VGSTUDIO MAX. To open it click Help > Show tutorials > Material Analysis > Automation with Macros and Batch Processing.

Set up the desired visualization, create a view, and export it as evaluation. During macro recording, import the evaluation and apply the view.

Alternatively, set up the desired visualization, create a bookmark, and export it as bookmark template. During macro recording, import the bookmark template and apply the bookmark.

Find more information in the tutorial about macros in VGSTUDIO MAX. To open it, click Help > Show tutorials > Material Analysis > Automation with Macros and Batch Processing.

Save the project via File > Pack and go, click Pack, and select the format .vgarchive.