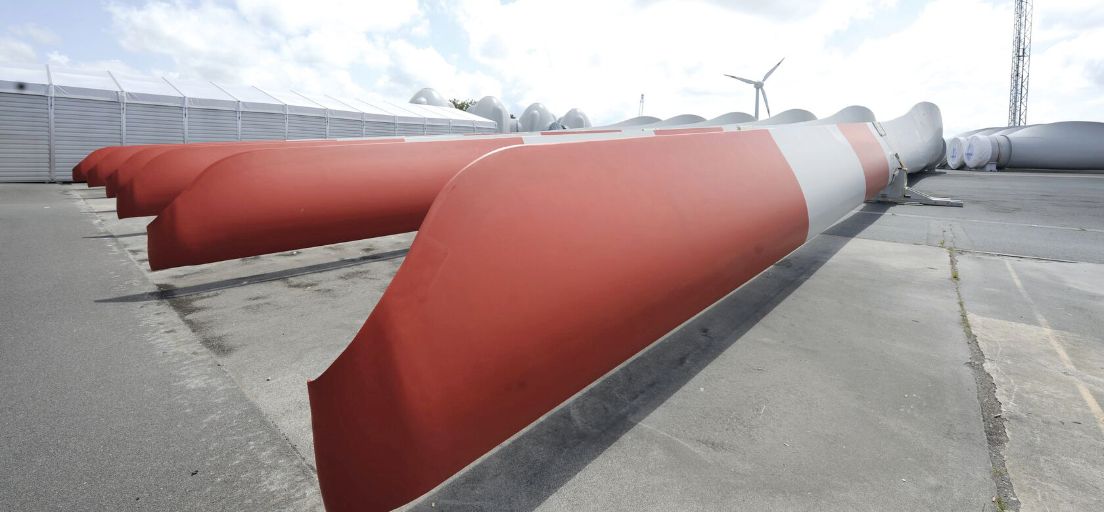

Solutions for Wind Turbine Blades

Design and manufacturing of efficient blades for wind turbines with best-in-class quality.

Ensure high-performance blade design, manufactured with the highest precision

Wind turbine blades are increasing in dimensions and facing new challenges such as weight, aero-elasticity, harsher onshore and offshore environments, and requirements for longer service lives. Hexagon provides solutions to design blades optimized for weight, aeroelasticity, efficiency, resilience and manufactured with highest precision while saving costs and time for production.

Materials engineering for wind turbine blades

Accelerate the material selection and development by enabling a better understanding of its mechanical behavior and its design impact on the performances. Different material microstructures and layups can be virtually defined and tested to efficiently screen and identify the material candidate with the required mechanical performance.

Materials Design

Material Modeling

Structural Analysis

CT Analysis

Products used

Structural simulation and design validation

Verify the design and accurately predict the structural behavior and life of the wind turbine blade, saving the need for costly physical prototypes and re-designs. Simulate structural behavior under numerous specific aeroelastic loading types and accurately predict overall structural life due to long-term fatigue.

Material Modeling

Structural Analysis

Products used

Optimize wind turbine noise performance

Reduce the time and effort required to ensure noise emission compliance of wind power blades by substituting physical with virtual tests. Predict wind turbine blade acoustic behavior at varying levels of fidelity for early stage design or late stage validation, enabling the optimization of blade shapes for noise reduction.

Computational Fluid Dynamics, Multiphysics Simulation

Simulation of the matrix curing process

Anticipate and remedy manufacturing issues, such as geometry deviations, before they arise by simulating the curing process. Multi-scale simulation of matrix curing using a thermo-visco-elastic model for the resin predicts residual stresses and resulting dimensional changes like spring-back, shrinkage and distortion.

Material Modeling

Structural Analysis

Products used

Blades and mold inspection

Increase the efficiency of high-quality production with fast, flexible and accurate inspection on the shopfloor and on site. Inspect the surfaces of blades and molds using a large-volume scanner, in either manual or semi-automated modes.

Dimensional Analysis, Automated Inspection

Process Control & Analytics

Products used

Inspection of flange flatness in milling machines

Reduce inspection times by up to 75% using contactless in-machine measuring, compared to measurements outside of the milling machine. Measure hundreds of projected points across a milling machine's flange, determining flange flatness by using specialist precision metrology software.

Dimensional Analysis

© 2025 Hexagon AB and/or its subsidiaries