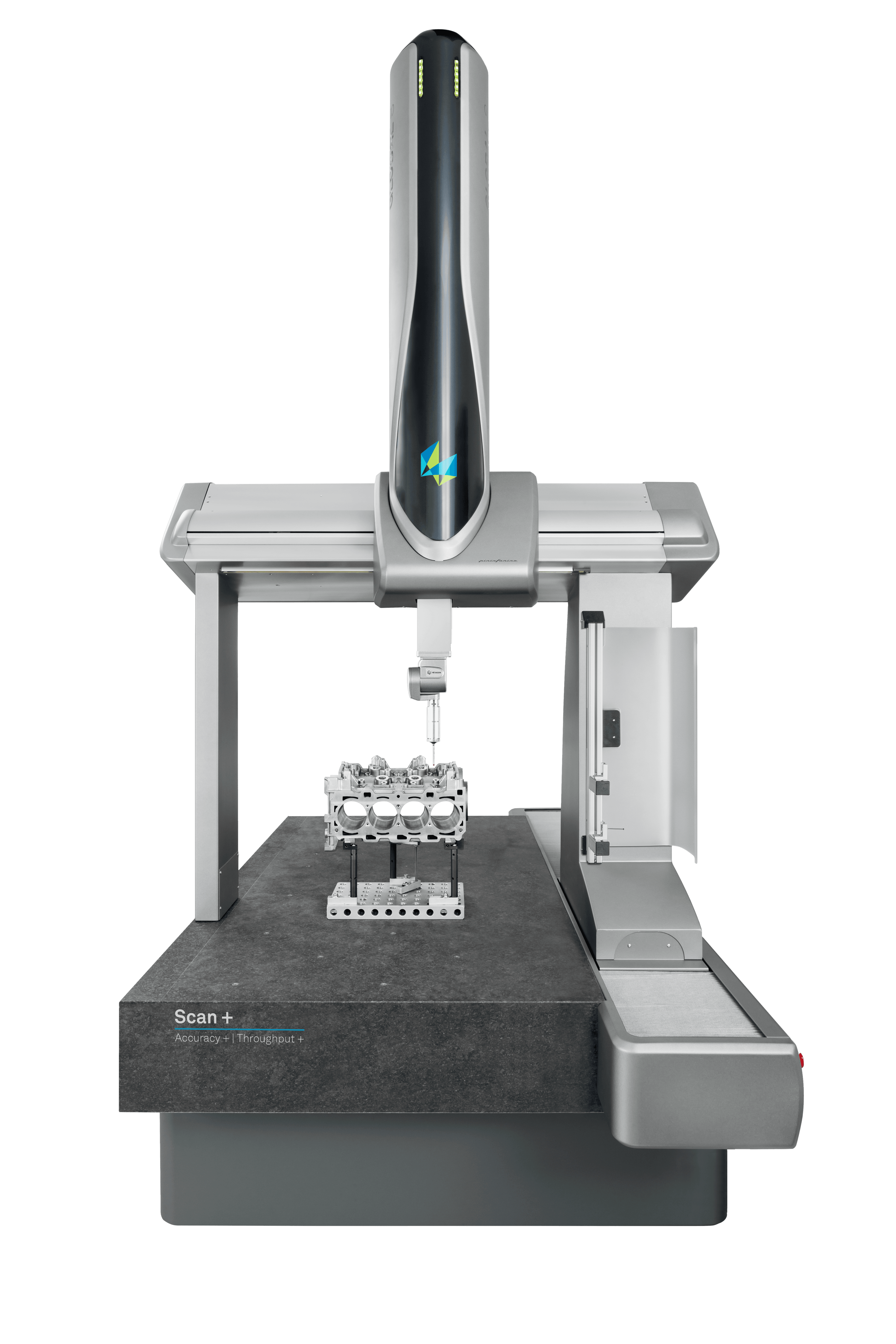

GLOBAL Scan+

Advanced tactile scanning for comprehensive GD&T analysis

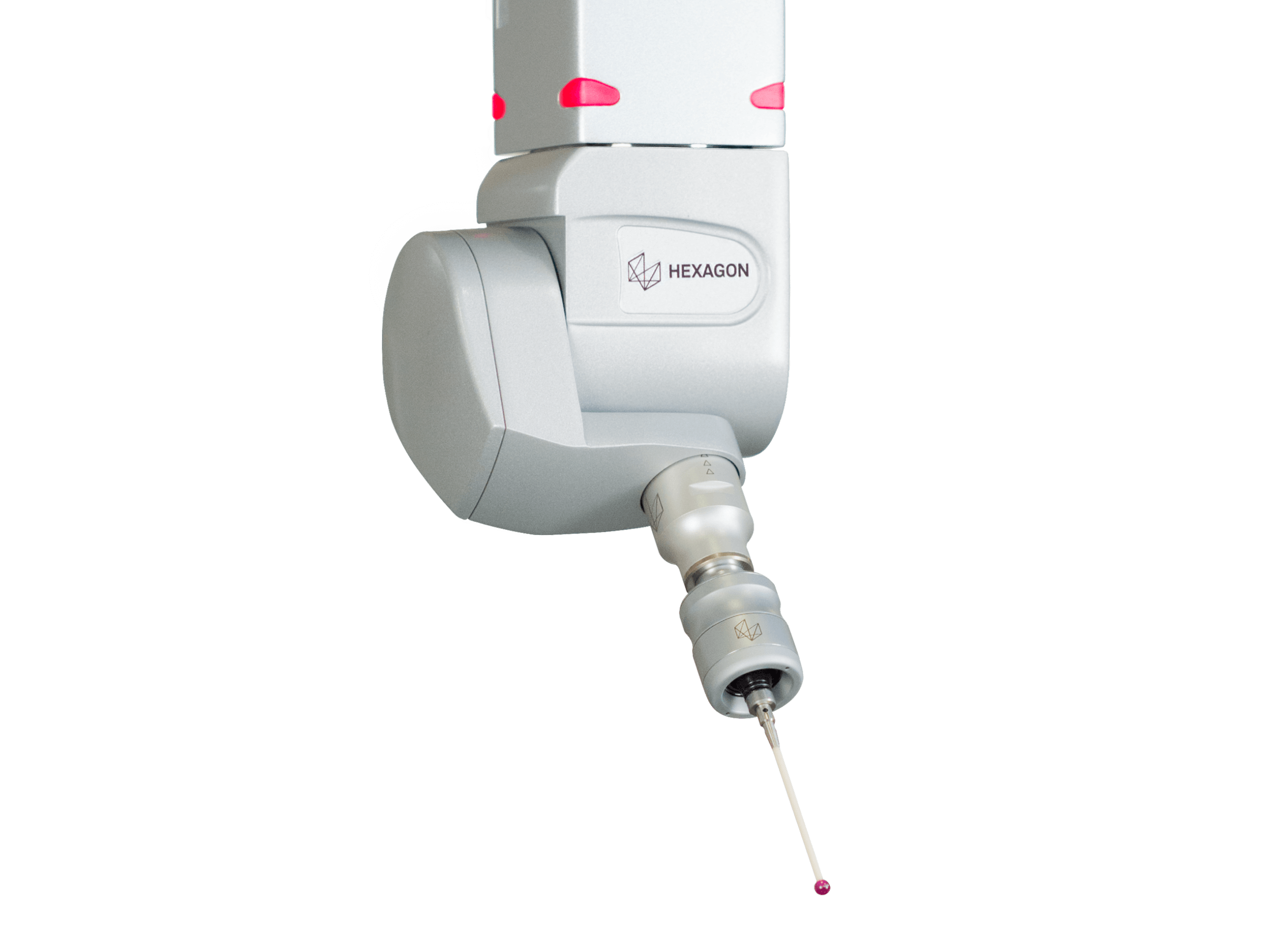

GLOBAL Scan+ adds tactile scanning to the range of possible applications. With tactile scanning, a large number of surface points are captured within a short time, enabling highly accurate form and profile measurements on functional parts.

GLOBAL Scan+ combines tactile scanning capability with the flexibility of an automatic probe head. The scanning probe can be positioned at various spatial angles, making accessing more complex workpieces easy. An accompanying styli changer rack accelerates the inspection process by enabling fast changes of styli configurations within a measuring program without restricting the available measurement volume.

Benefits And Features

High accuracy measurement

Measurement of features with tolerances in a low micron range.

Measurement speed

High scanning speed and measuring throughput.

High density tactile scanning

High measuring point density for an accurate evaluation of form errors.

Training and Resources

GLOBAL Scan+ Specifications

| Available Size (X, Y, Z)₁ | |

|---|---|

Sizes for GLOBAL S 05.05.05 / 05.07.05 / 07.07.05 / 07.10.07 / 09.12.08 / 09.15.08 / 09.20.08 / 12.15.10 / 12.22.10 / 12.30.10 / 15.22.10 / 15.30.10 Sizes for GLOBAL Advantage 15.20.14 / 15.26.14 / 15.30.14 / 20.33.15 / 20.40.15 / 20.33.18(₅) / 20.40.18(₅) | |

| Accuracy₂ | |

From 1.2μm + L/350, MPE(E0/E150)₃) [18-22 °C] From 1.4μm + L/250, MPE(E0/E150)₃) [16-26 °C] From 1.2μm + L/263, MPE(E0/E150)₄) [15-30 °C] | |

| Probe type compatibility | |

Touch-trigger probe Scanning probe | |

| Automation ready | |

YES | |

| Temperature specification | |

18-22 °C (lab temperature) 16-26 °C (extended temperature, option) 15-30 °C (shop floor packages, option)₄) |

₁ Sizes are expressed in dm. I.e., 05.07.05 means X = 500 mm; Y = 700 mm; Z = 500 mm

₂ According to ISO 10360-2 (2009)

₃ MPE(E0/E150) specifications are to be formally understood as MPE(E0E150)* for the case where non-normal CTE material calibrated test lengths are used. Length unit measure (L) in mm

₄ Shop-floor packages only for GLOBAL S

₅ Special on request

Take advantage of various learning opportunities

Visit the Nexus Academy Catalog for a complete list of educational content. You can enroll for training, complete self-paced courses, register for distance learning, classroom instruction, live training events, and download or print your completion certificate.

Dive into our documentation to explore the full potential of our product offerings

Your ultimate resource for practical guidance and support. Here you’ll find a wealth of step-by-step how-to guides, detailed tutorials, and handy tips and tricks. Whether you’re troubleshooting an issue or looking for ways to optimize your use of our products, our Documentation Center provides clear and concise information to help you get the most out of your experience.

Downloads are only available on the desktop version. Please access our site from a desktop to download.

This product does not offer any software downloads.

Our team is ready to help

Our technical support teams are on hand to answer your questions. Contact us through our online form and we will get right back to you.

You might be interested in...

Related products

© 2025 Hexagon AB and/or its subsidiaries