Solutions for Wind Turbine Gearboxes

Smart design, production and manufacturing of gearboxes focused on right-sizing, high efficiency and resilience.

Optimized designing and robust manufacturing of next-generation wind gearboxes

Wind turbine gearboxes are large and heavy, being one of the biggest contributors to turbine downtime in the field. Hexagon helps design and manufacture durable, fit-for-purpose, highly efficient gearboxes with a portfolio of simulation, CAM and inspection software and metrology hardware.

Design analysis and optimization of gearboxes

Design a gearbox and optimise it against a range of targets (cost, weight, durability, vibration, efficiency) in the minimum time and with minimized resources and project risk. Create a virtual model of a gearbox for design analysis, allowing the best design to be selected and the design fidelity to be gradually increased as the project progresses to virtual sign off.

System Dynamics

Structural Analysis

Products used

Virtual testing of designed and manufactured gearboxes

Reduce time and cost through virtual testing of wind turbine gearboxes during design and manufacturing. Verify the design before prototype manufacture and import measured data into a design simulation model to improve confidence that the design works as intended.

System Dynamics

Structural Analysis

Acoustic Simulation

Dimensional Analysis

Process Control & Analytics

First-time-right forging and welding of gear wheels

Save time and cost caused by multiple physical try-outs through virtual optimization of forging and welding sequences for a robust manufacturing process layout and extended service life. Simulate the forging of gear wheels. The resulting shape deviations and properties are then fed into a simulation of the welding sequence to determine possible thermally-induced distortions and residual stresses.

Virtual Manufacturing and Costing

First-time-right forging and rolling of bearings and shafts

Save time and cost caused by multiple physical try-outs through virtual optimization of processing steps and machine parameters for first-time-right production. Simulate the forging and rolling of bearings and shafts to predict part distortions and manufacturing issues like flow defects, machine overload or premature die failure.

Virtual Manufacturing and Costing

Efficient machining of gears

Substantially reduce the machining cycle time of gears through efficient machining strategies, ensuring smooth execution by building a Digital Twin that simulates the entire process. Prepare models for manufacturing, generate a toolpath NC program, then verify and optimize the toolpath through the creation of a Digital Twin and a simulation of the machining process.

CAD for CAM

Production Machining

CNC Simulation

Products used

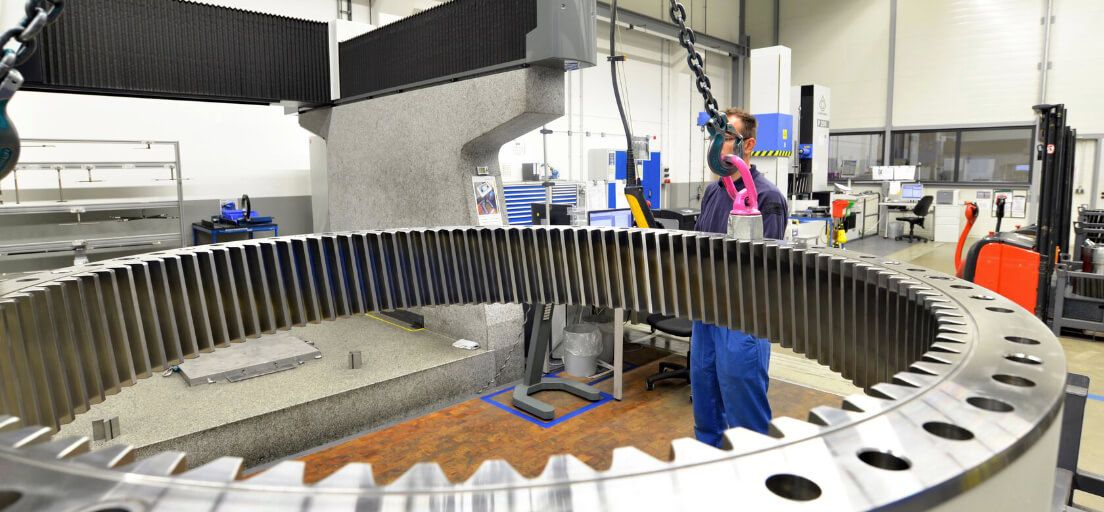

Efficient gear measurement

Avoid costly reworks and cost-intensive downtimes by inspecting even very large gears with a highly accurate and standard-compliant inspection system. Nearline/inline inspection of standard geometries and gears with stationary CMMs, standard-compliant evaluation and data transfer for statistical evaluation and/or monitoring of the manufacturing process, reverse engineering of unknown gears during maintenance.

Dimensional Analysis

Process Control & Analytics

Products used

Innovative inspection of gearbox housings

Geometrical and freeform elements of the housings are captured with ultra-high accuracy measurement methods, and the evaluation of the GD&T features is carried out with metrology software.

Dimensional Analysis

Process Control & Analytics

© 2026 Hexagon AB and/or its subsidiaries